Description

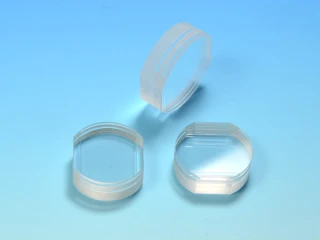

UM Optics High Precision Quartz Waveplates are premium polarization control components engineered for demanding industrial, scientific, and laser-based applications. Crafted from high-purity quartz crystal, these waveplates offer exceptional temperature stability and low wavelength sensitivity, ensuring reliable performance even in harsh operating environments.As a professional manufacturer, we provide a comprehensive range of quartz waveplates, including λ/4 (Quarter-Wave), λ/2 (Half-Wave), zero-order, and multi-order options. Each waveplate is precisely fabricated to deliver accurate phase retardation, with high extinction ratio (>1000:1 typical) for optimal polarization state conversion. The surface is coated with anti-reflective (AR) coating (customizable for UV, VIS, or IR wavelengths) to minimize light loss and enhance transmission efficiency.

High Quality Quartz Zero Order λ/2 λ/4 Waveplate (Retarder)

Specifications

| Waveplate Type: | Zero Order |

|---|---|

| Material: | Quartz |

| Mounting: | Unmounted |

| Shape: | Round |

| Size: | 25 mm |

| Center Wavelength: | 266 nm |

| Retardation: | Lambda/4 |

| Retardation Accuracy: | +/- Lambda/400 |

| Wavefront Distortion: | <= Lambda/4, <= Lambda/2, Custom |

| Surface Quality (Scratch-Dig): | 60-40 |

Features

- High-Purity Quartz Material: Ensures excellent optical uniformity and low birefringence variation, supporting high-precision polarization control.

- Superior Temperature Stability: Low temperature coefficient of quartz crystal (-0.001 nm/°C) prevents phase drift under temperature fluctuations, ideal for stable long-term operation.

- High Damage Threshold: Designed to withstand high-power laser irradiation (up to 10 J/cm² @ 1064nm, 10ns pulse), suitable for laser processing, laser ranging, and other high-power laser systems.

- Full Customization: Tailor-made solutions available for wavelength (200nm - 2000nm), phase retardation, size (from φ1mm to φ100mm), and coating. OEM/ODM services are supported to meet your specific optical system requirements.

- Strict Quality Control: Each waveplate undergoes rigorous inspection (interferometry, polarization measurement) before delivery, ensuring consistent quality and performance.

Applications

-

Laser Processing (Cutting, Welding, Marking): Enables precise polarization adjustment to optimize laser-material interaction and avoid processing defect

-

Polarization Imaging Systems: Controls light polarization to enhance contrast and detect subtle details in imaging applications

-

Polarimeters and Ellipsometers: Serves as a core component for accurate polarization analysis and material optical property measurement

-

Fiber Optic Communications: Enhances polarization management and compensates for polarization mode dispersion in telecom networks

-

3D Polarization Displays: Facilitates polarization signal separation to achieve clear stereoscopic imaging effects

-

Semiconductor Inspection: Controls polarization state to identify defects and irregularities in semiconductor wafers and devices

-

Glass Stress Analysis: Aids in visualizing stress distribution by manipulating polarized light passing through glass materials

-

Quantum Communication Research: Enables precise regulation of photon polarization states for quantum key distribution and related experiments

Frequently Asked Questions

What is the difference between Quarter Waveplates and Half Waveplates?

Can quartz waveplates be customized for specific wavelengths or sizes?

Why are anti-reflective (AR) coatings applied to quartz waveplates?

How to choose the right type of quartz waveplate (zero-order vs multi-order) for my project?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle