Description

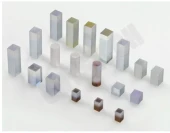

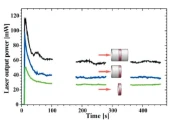

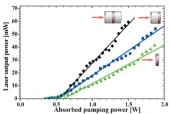

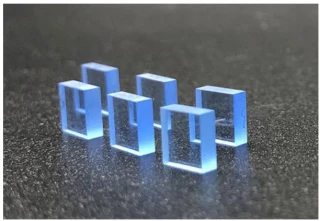

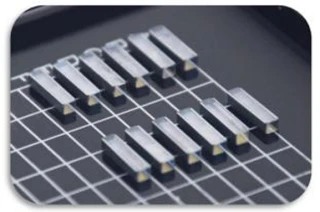

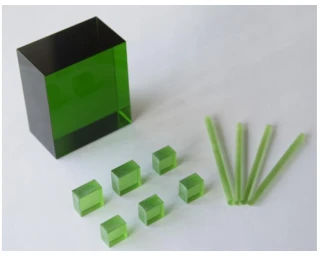

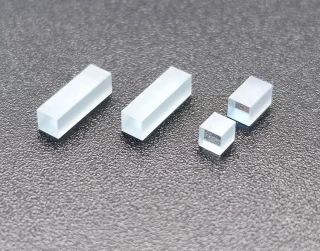

Discover the advanced capabilities of our Diffusion Bonded Crystals, expertly engineered for high-performance laser systems. These innovative crystals consist of two or three different crystal types, typically featuring an undoped crystal bonded to one or both ends of a doped crystal. Utilizing a specialized thermal bonding technique, these crystals are designed to significantly reduce thermal lensing effects, thereby enhancing laser performance and beam quality. This makes them exceptionally suitable for high-power laser applications. Our Diffusion Bonded Crystals are synonymous with superior laser efficiency and reliability. By minimizing the thermal lensing effect, these crystals enable lasers to operate at higher power levels with improved stability and precision. The bonding process not only enhances thermal management but also contributes to the overall robustness of the laser system, ensuring consistent performance in demanding environments. At Crystech, we take pride in our comprehensive in-house production capabilities, from crystal boules growth to cutting, polishing, and coating. This vertical integration allows us to offer various doping concentrations, ranging from 0.1% to 3%, with precise tolerance levels. Our commitment to quality and innovation ensures that our Diffusion Bonded Crystals meet the stringent demands of industrial and medical laser applications, providing quick delivery and competitive pricing.

High-Power Laser Nd:YVO4 Diffusion Bonded Crystal

Specifications

| Type Of Crystal: | Bonded YAG Crystal |

|---|---|

| AR Coating: | Uncoated, Both sides, One side |

| Parallelism: | ≤10″ |

| Coatings: | AR@1064nm & 808nm |

| Clear Aperture: | ≥95% |

| Wavefront Distortion: | λ/8@633nm |

| Chips: | <0.1mm |

| Flatness: | λ/10@633nm |

| Chamfer: | <0.1mm x 45° |

| Doping Concentration Range: | 0.1% to 3% |

| Perpendicularity: | ≤10′ |

| Scratch/Dig: | 20/10 |

| Dimension Tolerance Length: | (+0.5/-0.1) mm |

| Dimension Tolerance Height: | (+/-0.1) mm |

| Dimension Tolerance Width: | (+/-0.1) mm |

| Doping Concentration Tolerance (atm% ≥ 1%): | ±0.1% |

| Doping Concentration Tolerance (atm% < 1%): | ±0.05% |

Features

- Improved and Enhanced Thermal-Handling Performance: Diffusion Bonded Crystals are designed to effectively manage thermal loads, making them ideal for high-power laser applications.

- Decreased Thermal Lensing Effect: These crystals significantly reduce thermal lensing, enhancing the stability and quality of laser beams.

- Increased Laser Performance and Beam Quality: By optimizing the laser medium, these crystals boost overall laser efficiency and beam quality.

- Versatile Applications: Suitable for use in industrial lasers, medical lasers, and primarily in end-pumped CW and QCW high-power solid-state lasers.

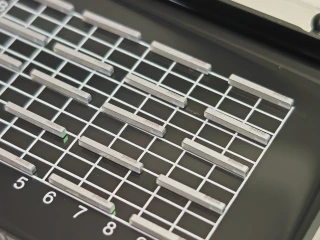

- Comprehensive In-House Manufacturing: Crystal boules growth, cutting, polishing, and coating are all conducted in-house, ensuring high quality and consistency.

- Customizable Doping Concentrations: Available in various doping concentrations from 0.1% to 3%, with precise tolerances (±0.05% for atm% <1%, ±0.1% for atm% ≥1%).

- Quick Delivery and Competitive Pricing: Benefit from fast delivery times and competitive pricing, enhancing your operational efficiency and cost-effectiveness.

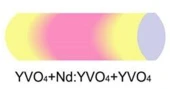

- Multiple Configurations Available: Choose from different types such as YVO4+Nd:YVO4, YVO4+Nd:YVO4+YVO4, YAG+Nd:YAG, YAG+Nd:YAG+YAG, and Nd:YAG+Cr:YAG.

- Precision Specifications: Dimension tolerances of Width (+/-0.1) * Height (+/-0.1) * Length (+0.5/-0.1 mm), Scratch/Dig 20/10, Perpendicularity ≤10′, Parallelism ≤10″, Chamfer <0.1 mm x 45°.

- Optical Quality: Flatness λ/10@633 nm, Wavefront Distortion λ/8@633 nm, Clear Aperture ≥95%.

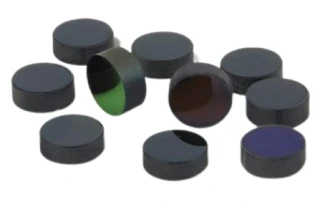

- Custom Coatings: Standard AR coatings at 1064 nm & 808 nm, with other coatings available upon request.

- End Types: Available in Parallel and Anti-Parallel configurations to suit specific application needs.

Applications

- Industrial Laser

- Medical Laser

- Mainly used for end-pumped CW and QCW high power solid-state lasers.

Frequently Asked Questions

What is a Diffusion Bonded Crystal?

What are the benefits of using Diffusion Bonded Crystals?

What are the applications of Diffusion Bonded Crystals?

What types of Diffusion Bonded Crystals are available?

What is the dimension tolerance for these crystals?

What coatings are available for Diffusion Bonded Crystals?

What are the company's advantages in producing Diffusion Bonded Crystals?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle