Description

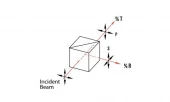

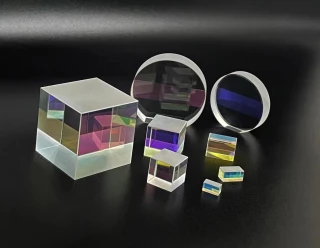

The Non-Polarizing Plate Beamsplitters from Rocky Mountain Instrument Co. are expertly designed to divide an incident, monochromatic beam into both reflected and transmitted components, adhering to a specified intensity ratio. These beamsplitters are essential for applications where maintaining the polarization characteristics of the incident beam is crucial. This ensures that the integrity of the polarization is preserved, making them an ideal choice for precision optical systems.

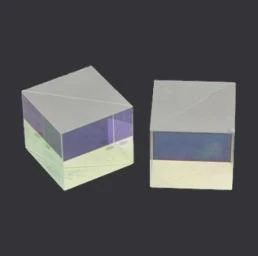

Each plate is meticulously coated on one side with an all-dielectric, non-polarizing, partial reflection coating. This advanced coating technology is paired with a high-efficiency, narrowband anti-reflection coating on the reverse side. This dual-coating approach not only enhances the performance of the beamsplitters but also ensures minimal loss of light and superior clarity in optical applications.

At Rocky Mountain Instrument Co., we pride ourselves on a collaborative service philosophy, working closely with our clients to address even the most technically demanding requirements. By engaging with our customers during the early stages of development, we transition prototype concepts into efficient, manufacturable solutions. Our commitment to excellence and innovation is reflected in every product we offer, ensuring that our clients receive unparalleled quality and performance.

Non-Polarizing ZnSe Plate Beamsplitters for Monochromatic Beam Division

Specifications

| Material: | ZnSe |

|---|---|

| Wavelength Range: | 9000 – 11000 nm |

| Max Beam Deviation: | 3 arcmin |

| Surface Figure: | Lambda/40 @ 10.6 μm |

| Surface Quality: | 40-20 Scratch-Dig |

| Large Dimension And Thickness: | Custom |

Features

- Non-Polarizing Plate Beamsplitters: Designed to divide an incident, monochromatic beam into reflected and transmitted components while maintaining the polarization characteristics of the incident beam.

- High-Quality Coatings: One side is coated with a dielectric, non-polarizing, partial reflection coating, and the reverse side features a high-efficiency, narrowband, anti-reflection coating.

- Standard Materials: Available in BK7, UVFS, and ZnSe materials.

- Angle of Incidence: Optimized for 45º angle of incidence.

- Surface Figure: Achieves λ/20 at 632 nm for BK7 and UVFS, and λ/40 at 10.6 µm for ZnSe.

- Surface Quality: 10-5 for BK7 and UVFS, 40-20 for ZnSe, ensuring high precision.

- Diameter Tolerance: Precisely manufactured with a tolerance of +0.000", –0.010".

- Thickness Tolerance: Maintained within ±0.010".

- Wedge: ≤ 3 arc minutes for minimized beam deviation.

- Bevels: 0.010" – 0.030" at 45º for edge protection.

- Clear Aperture: Central 85% of the diameter is clear, ensuring optimal use.

- Reflectance: Adjustable between 10% and 90% ± 3% with |R – Rs.p| ≤ 3%.

- Anti-Reflection Coating: Provides unpolarized reflectance ≤ 0.5% at 45º.

Applications

- Laser Systems: Ideal for maintaining beam polarization characteristics in laser applications.

- Optical Instrumentation: Used in systems requiring precise control of light reflection and transmission.

- Telecommunications: Suitable for splitting beams in fiber optic communication systems.

- Scientific Research: Essential in experiments where beam polarization must remain unchanged.

- Medical Devices: Utilized in laser-based medical equipment to ensure accurate light delivery.

- Imaging Systems: Enhances image quality by controlling light path in high-resolution cameras and microscopes.

- Industrial Applications: Used in manufacturing processes involving laser cutting and welding.

Frequently Asked Questions

What is the ZnSe RMI Cube Beamsplitter used for?

What is the surface quality of the ZnSe RMI Cube Beamsplitter?

What is the diameter tolerance for the ZnSe RMI Cube Beamsplitter?

What is the reflectance range for the ZnSe RMI Cube Beamsplitter?

What is the angle of incidence for the ZnSe RMI Cube Beamsplitter?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle