Description

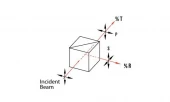

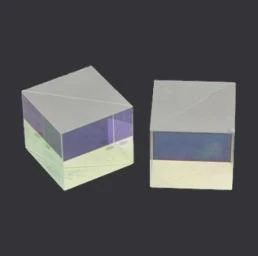

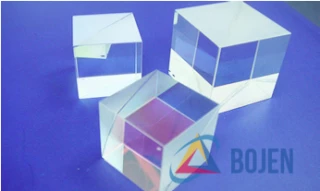

Non-Polarizing Plate Beamsplitters are essential optical components designed to divide an incident monochromatic beam into reflected and transmitted components with a specified intensity ratio. These beamsplitters are meticulously engineered to maintain the polarization characteristics of the incident beam, making them ideal for applications where polarization preservation is crucial. The innovative design involves coating one side of the plate with an all-dielectric, non-polarizing, partial reflection coating, while the reverse side is treated with a high-efficiency, narrowband, anti-reflection coating.

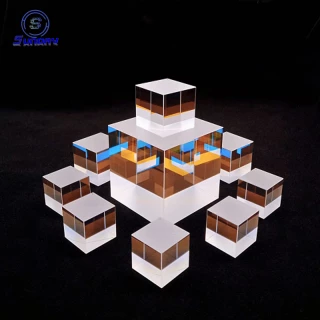

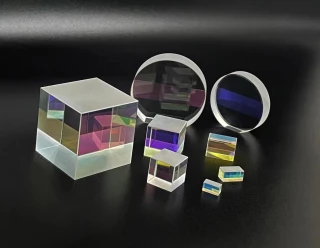

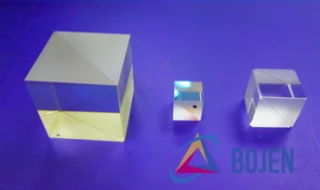

The construction of these beamsplitters utilizes high-quality materials such as BK7, UVFS, and ZnSe, ensuring exceptional performance and reliability. The precise angle of incidence is set at 45º, which is a standard in the industry for optimal operation. The surface quality of these beamsplitters is meticulously controlled, with specifications such as a surface figure of λ/20 at 632 nm for BK7 and UVFS, and λ/40 at 10.6 µm for ZnSe, ensuring superior optical clarity and minimal distortion.

Rocky Mountain Instrument Co. is committed to delivering high-quality optical solutions, and their non-polarizing plate beamsplitters exemplify this dedication. With a focus on precision, these beamsplitters offer a diameter tolerance of +0.000", –0.010", and a thickness tolerance of ±0.010". The wedge is maintained at ≤ 3 arc minutes, and bevels range from 0.010" to 0.030" at 45º, ensuring a high degree of accuracy and consistency. The clear aperture is centrally located and covers 85% of the diameter, maximizing the usable area of the beamsplitter.

Reflectance levels are carefully controlled, with specifications ranging from 10% to 90% ± 3%, and the anti-reflection coating ensures that unpolarized reflectance is kept at R ≤ 0.5% at 45º. These precise specifications make the non-polarizing plate beamsplitters from Rocky Mountain Instrument Co. a reliable choice for those seeking to maintain the integrity of their optical systems.

Non-Polarizing BK7 UVFS, and ZnSe Plate Beamsplitters for Monochromatic Beam Applications

Specifications

| Material: | N-BK7, UV Fused Silica |

|---|---|

| Wavelength Range: | 300 – 2000 nm |

| Max Beam Deviation: | 3 arcmin |

| Surface Quality: | 10-5 Scratch-Dig |

| Surface Figure: | Lambda/20 @ 632 nm |

| Large Dimension And Thickness: | Custom |

Features

- Non-Polarizing Design: Maintains the polarization characteristics of the incident beam, ideal for applications requiring precise polarization control.

- High-Quality Materials: Available in BK7, UVFS, and ZnSe for versatile application use.

- Optimal Angle of Incidence: Designed for a 45º angle of incidence, ensuring maximum performance.

- Precise Diameter and Thickness Tolerance: Diameter tolerance of +0.000", –0.010"; thickness tolerance of ±0.010".

- Minimal Wedge: ≤ 3 arc minutes to ensure minimal beam deviation.

- Defined Bevels: 0.010" – 0.030" at 45º for edge protection.

- Clear Aperture: Central 85% of diameter, providing a large usable area.

- Adjustable Reflectance: Reflectance range of 10% ≤ R ≤ 90% ± 3% with |R – Rs.p| ≤ 3%.

- Advanced Anti-Reflection Coating: Unpolarized R ≤ 0.5% at 45º, enhancing transmission efficiency.

Applications

- Optical Systems: Ideal for systems requiring the division of a monochromatic beam into reflected and transmitted components while maintaining polarization characteristics.

- Laser Applications: Suitable for laser systems where maintaining the polarization of the incident beam is crucial.

- Scientific Research: Used in experiments and setups that require precise control over beam splitting and polarization.

- Imaging Systems: Can be integrated into imaging systems where non-polarizing characteristics are necessary to prevent image distortion.

- Telecommunications: Utilized in optical communication systems to manage signal paths without altering polarization states.

- Optical Testing Equipment: Essential in testing equipment where accurate beam splitting and polarization maintenance are required for precise measurements.

- Microscopy: Applied in advanced microscopy techniques that benefit from non-polarizing beam splitters to enhance image clarity.

- Holography: Used in holographic setups to ensure high-quality image reproduction by maintaining the desired beam characteristics.

Frequently Asked Questions

What is the surface figure for the RMI Cube Beamsplitter?

What is the clear aperture for the RMI Cube Beamsplitter?

What is the reflectance range for the RMI Cube Beamsplitter?

What is the angle of incidence for the RMI Cube Beamsplitter?

What is the RMI Cube Beamsplitter made of?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle