Description

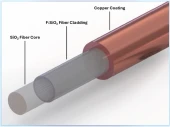

Mir Photonics LLC is proud to present its Copper-alloy Coated Silica Fibers, a breakthrough in fiber technology designed for the most challenging environments. These fibers are engineered to excel where traditional fiber solutions fall short, offering exceptional performance in extreme conditions such as high temperatures, high vacuum, and harsh operational settings. With a focus on industrial, scientific, and aerospace applications, these fibers provide unparalleled optical stability combined with robust thermal and mechanical resilience.

What sets these copper-alloy coated fibers apart is their ability to maintain the inherent benefits of traditional silica-silica fibers while significantly enhancing mechanical strength and durability. The metallic coating not only boosts resistance to fatigue and mechanical stress but also ensures superior performance compared to polymer-coated fibers. This makes them an ideal choice for demanding applications where reliability and longevity are critical.

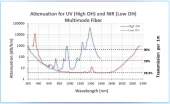

The optical transmission capabilities of these fibers are impressive, covering a broad spectrum from 220 to 2400 nm. This wide range is achieved through the selection of UV or NIR silica fiber cores, allowing for versatile use across various optical and spectroscopic applications. Remarkably, these fibers maintain consistent performance across an extreme temperature range, from cryogenic levels as low as –270°C to continuous operation at temperatures up to 600°C. Additionally, they can withstand humidity levels of up to 100% without compromising their optical or mechanical integrity, ensuring reliable operation in diverse environmental conditions.

Copper-Alloy Coated Silica Fibers

Specifications

| Mode Field Diameter (MFD): | 4 um |

|---|---|

| Wavelength Range: | 200 – 2400 nm |

| Fiber Core Material: | Silica |

| Optical Transmission Range: | 220 to 2400 nm |

| Min Operating Temperature: | -270°C |

| Max Operating Temperature: | 600°C |

| Humidity Range: | Up to 100% |

| Fiber Core Diameters: | Single mode: 4 – 9 μm; Multimode: 50; 62.5; 100; 200; 400; 600; 800; 1000 μm |

| Cu-alloy Coating Thickness: | 15 – 50 μm |

| Standard Numerical Aperture (NA): | 0.22 ± 0.02 |

| Available Numerical Aperture (NA): | 0.12 ± 0.02 | 0.26 ± 0.02 |

| Minimal Bending Radius (Long Term): | 200 x fiber outer diameter |

| Minimal Bending Radius (Short Term): | 100 x fiber outer diameter |

| Tensile Strength (Short Gauge): | 3.5 – 6 GPa |

| Two Point Bending Strength: | >10 GPa |

| Static Fatigue Parameter: | >100 |

Features

- Extreme Temperature Resistance: Operates reliably from cryogenic levels at -270°C up to 600°C, ideal for demanding environments.

- Wide Optical Transmission Range: Supports wavelengths from 220 to 2400 nm, suitable for a variety of optical and spectroscopic applications.

- Enhanced Mechanical Strength: Copper-alloy coating significantly improves durability and resistance to mechanical stress compared to polymer-coated fibers.

- High Humidity Tolerance: Maintains optical and mechanical integrity even at 100% humidity levels.

- Versatile Core/Cladding Options: Available in Step Index Pure Fused Silica Core with Fluorine Doped Silica Cladding and Graded Index Germanium Doped Fused Silica Core.

- Variety of Fiber Core Diameters: Single mode options from 4 – 9 μm and multimode options including 50, 62.5, 100, 200, 400, 600, 800, and 1000 μm.

- Customizable Numerical Aperture (NA): Standard NA of 0.22 ± 0.02, with available options of 0.12 ± 0.02 and 0.26 ± 0.02.

- Robust Coating Thickness: Copper-alloy coating thickness ranges from 15 – 50 μm, depending on fiber diameter.

- Superior Bending and Tensile Strength: Minimal bending radius of 200x fiber outer diameter (long term) and 100x (short term), with tensile strength ranging from 3.5 – 6 GPa and two-point bending strength over 10 GPa.

- High Static Fatigue Parameter: Exceeds 100, ensuring long-term reliability and performance.

Applications

- High Temperature Applications: Suitable for environments with temperatures ranging from cryogenic levels (-270°C) to 600°C.

- High Vacuum Environments: Ideal for use in high vacuum conditions where traditional fibers may fail.

- Harsh Operational Environments: Engineered for demanding industrial, scientific, and aerospace applications.

- Optical and Spectroscopic Applications: Wide optical transmission range from 220 to 2400 nm, supporting both UV and NIR applications.

- Humidity Tolerance: Maintains performance in environments with up to 100% humidity.

- Mechanical Strength and Durability: Copper-alloy coating enhances mechanical strength, durability, and resistance to fatigue and stress.

- Flexible Fiber Core Options: Available in single mode (4 – 9 μm) and multimode (50, 62.5, 100, 200, 400, 600, 800, 1000 μm) core diameters.

- Customizable Numerical Aperture: Standard NA of 0.22 ± 0.02, with options for 0.12 ± 0.02 and 0.26 ± 0.02.

- Robust Bending Capabilities: Minimal bending radius of 200x fiber outer diameter for long-term use and 100x for short-term use.

- High Tensile and Bending Strength: Tensile strength of 3.5 – 6 GPa and two-point bending strength greater than 10 GPa.

- Static Fatigue Resistance: Static fatigue parameter greater than 100, ensuring long-term reliability.

Frequently Asked Questions

What are Copper-alloy Coated Silica Fibers?

What temperature range can these fibers operate in?

What are the advantages of copper-alloy coating compared to polymer-coated fibers?

What is the optical transmission range of these fibers?

What are the available fiber core diameters?

What is the standard numerical aperture (NA) of these fibers?

How do these fibers perform in high humidity conditions?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle