Description

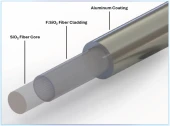

Mir Photonics’ Aluminum Coated Silica Fibers are engineered to excel in environments where traditional polymer-coated fibers fall short. These fibers are the ideal solution for applications requiring exceptional reliability under extreme conditions such as high temperatures and high vacuum. The innovative aluminum coating not only provides superior thermal management but also ensures long-term durability, making these fibers perfect for use in harsh industrial, scientific, and aerospace settings. The robust aluminum layer effectively protects the fibers from heat, radiation, and aggressive sterilization processes, maintaining stable optical performance throughout.

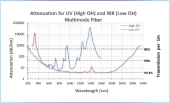

While retaining the inherent advantages of standard silica-silica fibers, such as excellent optical clarity, low attenuation, and chemical inertness, the aluminum coating significantly enhances mechanical strength and fatigue resistance. This enhancement offers superior protection against micro-bending, vibration, and repeated mechanical stress, ensuring the fibers remain reliable even under demanding conditions. The aluminum-coated fibers are designed to withstand a broad optical transmission range from 220 to 2400 nm, making them versatile for various applications, including spectroscopy, sensing, medical, and industrial laser systems.

These fibers are remarkably resilient, maintaining consistent performance across an extreme temperature range from cryogenic conditions as low as –270°C to continuous operation at 450°C. This wide temperature tolerance, combined with their robust construction, makes Mir Photonics’ Aluminum Coated Silica Fibers a dependable choice for any application that demands high performance in challenging environments.

Aluminum Coated Silica Fibers

Specifications

| Mode Field Diameter (MFD): | 2.5 um |

|---|---|

| Wavelength Range: | 200 – 2400 nm |

| Fiber Core Material: | Silica |

| Core/Cladding Material: | Step Index Pure Fused Silica Core / Fluorine Doped Silica Cladding |

| Graded Index: | Germanium Doped Fused Silica Core / Pure Fused Silica |

| Fiber Core Diameters, μm: | Single mode: 2.5 – 9; Multimode: 50; 62.5; 100; 200; 400; 600; 800; 1000 |

| Al Coating Thickness, μm: | 15 – 150 |

| Standard Numerical Aperture (NA): | 0.22 ± 0.02 |

| Available Numerical Aperture (NA): | 0.12 ± 0.02 | 0.26 ± 0.02 |

| Min Operating Temperature, °C: | -270 |

| Max Operating Temperature, °C: | 450 |

| Humidity Range: | Up to 100% |

| Minimal Bending Radius (long Term): | 200 x fiber outer diameter |

| Minimal Bending Radius (short Term): | 100 x fiber outer diameter |

| Tensile Strength (short Gauge), GPa: | 3.5 – 6 |

| Two Point Bending Strength, GPa: | >10 |

| Static Fatigue Parameter: | >100 |

Features

- Exceptional Reliability: Designed for high temperatures, high vacuum, and extreme environmental conditions, making them ideal for industrial, scientific, and aerospace applications.

- Advanced Thermal Management: Aluminum coating ensures efficient thermal management and long-term durability, even under heat, radiation, or aggressive sterilization processes.

- Superior Optical Performance: Retains the benefits of standard silica-silica fibers, including excellent optical clarity and low attenuation.

- Enhanced Mechanical Strength: The metallic coating provides increased mechanical strength and fatigue resistance, protecting against micro-bending, vibration, and repeated mechanical stress.

- Broad Optical Transmission Range: Supports a wide variety of applications with a range from 220 to 2400 nm, suitable for spectroscopy, sensing, medical, and industrial laser systems.

- Extreme Temperature Resilience: Maintains consistent performance from cryogenic conditions as low as –270°C up to continuous operation at 450°C.

Applications

- High Temperature and Vacuum Applications: Ideal for environments where conventional polymer-coated fibers fail, such as high temperatures and high vacuum conditions.

- Industrial and Scientific Use: Suitable for harsh industrial and scientific environments, providing stable optical performance.

- Aerospace Applications: Designed to withstand extreme conditions, making them perfect for aerospace use.

- Efficient Thermal Management: Aluminum coating ensures efficient thermal management and long-term durability.

- Radiation and Sterilization Resistance: Withstands heat, radiation, and aggressive sterilization processes.

- Optical Clarity and Low Attenuation: Retains benefits of standard silica-silica fibers, including excellent optical clarity and low attenuation.

- Mechanical Strength and Fatigue Resistance: Enhanced mechanical strength and fatigue resistance protect against micro-bending, vibration, and mechanical stress.

- Broad Optical Transmission Range: Supports a wide variety of applications with a transmission range from 220 to 2400 nm.

- Versatile Applications: Suitable for spectroscopy, sensing, medical, and industrial laser systems.

- Extreme Temperature Performance: Maintains performance from cryogenic conditions as low as –270°C up to continuous operation at 450°C.

Frequently Asked Questions

What are Mir Photonics' Aluminum Coated Silica Fibers used for?

What is the optical transmission range of these fibers?

What are the benefits of the aluminum coating on these fibers?

What is the operating temperature range for these fibers?

What are the available fiber core diameters?

What is the standard numerical aperture (NA) for these fibers?

What is the tensile strength of these fibers?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle