Description

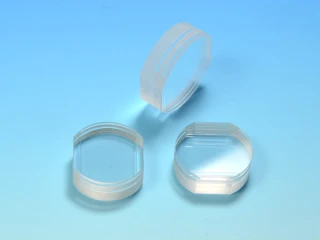

Tower Optical's 10mm Zero Order Waveplates are meticulously crafted to deliver exceptional performance in optical applications. These waveplates are constructed using high-quality Crystal Quartz, ensuring a clear aperture of 8mm. The design incorporates an air-spaced configuration, featuring a stainless steel spacer between two crystal quartz plates, which enhances the zero order capability. This configuration offers superior thermal stability and power handling compared to contacted or cemented waveplates, eliminating the risk of failure associated with contacted waveplates coming apart.

One of the standout features of these waveplates is their reduced sensitivity to temperature variations, making them a reliable choice for precision applications. The angular alignment of the waveplates is highly accurate, contributing to their overall performance. Each waveplate is AR coated on both sides, minimizing reflection losses and ensuring optimal transmission. The standard retardations available are ½ or ¼ wave, catering to a variety of optical needs.

These waveplates are available in both unmounted and mounted configurations. The unmounted version has a diameter of 10mm, while the mounted versions are available in 12.7mm or 25.4mm anodized aluminum mounting rings, maintaining an 8mm clear aperture. Tower Optical offers a range of standard wavelengths, with the flexibility to supply waveplates at wavelengths within a 10–20nm range from those listed. Custom wavelengths are also available upon request, demonstrating Tower Optical's commitment to meeting diverse customer requirements.

Zero Order Waveplate 10mm-Z-L/4-248nm

Specifications

| Waveplate Type: | Zero Order |

|---|---|

| Material: | Quartz |

| Mounting: | Mounted, Unmounted |

| Shape: | Round |

| Size: | 10 mm |

| Center Wavelength: | 248 nm |

| Retardation: | Lambda/4 |

| Wavefront Distortion: | <= Lambda/4, <= Lambda/2 |

Features

- High-Performance Crystal Quartz Retarder: Provides superior optical performance with a clear aperture of 8mm.

- Zero Order Capability: Air-spaced design with a stainless steel spacer enhances thermal stability and power handling.

- Temperature Insensitivity: Less sensitive to temperature variations compared to multi-order waveplates.

- Accurate Angular Alignment: Ensures precise alignment for optimal performance.

- AR Coated for Enhanced Performance: Anti-reflective coating on both sides reduces reflection to less than 0.25% per surface.

- Wide Wavelength Range: Available in standard wavelengths from 237nm to 2021nm, with custom wavelengths available on request.

- High Damage Threshold: Can withstand 1 kW/cm² CW and 3.5 J/cm² @ 10 ns.

- Precision Specifications: Wavefront distortion of λ/10 @ 632.8nm and surface quality of 10-5 Scratch/Dig.

- Multiple Mounting Options: Available unmounted with a 10mm diameter or mounted in 12.7mm or 25.4mm anodized aluminum rings.

- Standard Retardations: Offered in ½ or ¼ wave retardations for versatile applications.

- Custom Orders Available: Tailored solutions to meet specific wavelength requirements within a 10–20nm range.

Applications

- Laser Systems: Enhance the performance of laser systems by providing precise retardation with minimal wavefront distortion.

- Optical Instrumentation: Used in various optical instruments for polarization control and analysis.

- Telecommunications: Improve signal quality in fiber optic communication systems by managing polarization states.

- Medical Devices: Applied in medical imaging and laser surgery equipment for accurate polarization control.

- Scientific Research: Essential in laboratories for experiments requiring precise control of light polarization.

- Photography and Imaging: Used in high-quality cameras and imaging systems to enhance image clarity and contrast.

- Industrial Applications: Employed in manufacturing processes that require precise laser cutting and welding.

- Defense and Aerospace: Utilized in targeting systems and surveillance equipment for enhanced accuracy and performance.

Frequently Asked Questions

Are Tower's 10mm waveplates mounted or unmounted?

What is the range of wavelengths that Tower offers for the 10mm zero order waveplates?

What is the difference between zero order and multi-order waveplates?

What is the clear aperture of Tower's 10mm Zero order waveplates?

Are Tower's 10mm waveplates AR coated?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle