Description

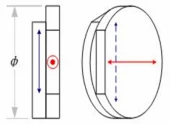

Photonchina presents its expertly crafted waveplates, a crucial optical component designed to manipulate the polarization state of light without any attenuation, deviation, or displacement of the beam. These waveplates are indispensable for applications requiring high damage thresholds and stable retardation over varying temperatures, making them ideal for use with lasers and infrared light sources. The waveplates are designed to handle light incidents normal to the surface, where the components polarized parallel and perpendicular to the optical axis propagate differently, resulting in a phase shift known as retardance.

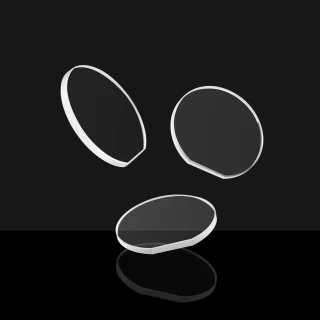

The fabrication of Photonchina's waveplates begins with the precise cutting of quartz materials, ensuring the axes are oriented within a few arcminutes. This meticulous process is followed by polishing to achieve a laser-quality finish, arcsecond parallelism, and a wavefront accuracy of less than λ/10. The thickness tolerance is maintained to a fraction of a micron, showcasing the precision of Photonchina's manufacturing standards. Specially-trained optical technicians utilize purpose-built test equipment to verify retardation tolerances, ensuring the highest quality and performance. After anti-reflective coating, the waveplates are matched in pairs and aligned accurately within their cell mounts.

Photonchina offers two primary types of waveplates: half waveplates and quarter waveplates. A half waveplate is engineered to rotate linearly polarized light to any desired orientation, with the rotation angle being twice the angle between the incident polarized light and the optical axis. On the other hand, a quarter waveplate is designed to transform linearly polarized light into circularly polarized light when input at a 45-degree angle to the axis, and vice versa. The thickness of the quarter waveplate ensures a phase difference of 1/4 wavelength or a certain multiple thereof, providing flexibility in various optical applications.

Photonchina provides standard waveplate wavelengths, including 355 nm, 532 nm, 632.8 nm, 808 nm, 850 nm, 980 nm, 1064 nm, 1310 nm, 1480 nm, 1550 nm, and 1590 nm. Additionally, Photonchina caters to specific needs by offering other wavelengths within the range of 200-2300 nm. This extensive range ensures that Photonchina's waveplates can meet diverse requirements across different industries and applications.

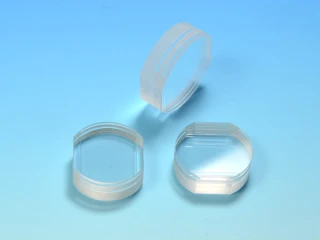

Photonchina Quartz Waveplates: Half and Quarter Wave Retarders

Specifications

| Waveplate Type: | Zero Order, Multiple Order, Achromatic |

|---|---|

| Material: | Quartz and MgF2, MgF2, Quartz, N-BK7, Custom |

| Mounting: | Mounted, Unmounted |

| Shape: | Round, Square, Rectangle, Custom |

| Size: | 1 mm |

| Center Wavelength: | 850 nm |

| Retardation: | Lambda/2, Lambda/4, Lambda, Other |

| Retardation Accuracy: | +/- Lambda/20, Custom, +/- Lambda/50, +/- Lambda/100, +/- Lambda/500, +/- Lambda/400, +/- Lambda/300, +/- Lambda/200 |

| Wavefront Distortion: | <= Lambda/20, <= Lambda/10, <= Lambda/8, <= Lambda/6, <= Lambda/4, <= Lambda/2, Custom |

| Surface Quality (Scratch-Dig): | 10-5, 20-10, 40-20, 60-40, 80-50 |

| Clear Aperture: | >90% |

| Damage Threshold: | >500 MW/cm2 |

Features

- High-Quality Quartz Material: Photonchina's waveplates are crafted from premium crystal quartz, ensuring durability and performance.

- Precision Fabrication: The waveplates are cut and polished to a laser-quality finish with arcsecond parallelism and <λ/10 wavefront.

- Retardation Accuracy: Retardation tolerances are verified using specialized test equipment, ensuring precise performance.

- Anti-Reflective Coating: Each waveplate is coated to minimize reflection and maximize transmission efficiency.

- Zero Order and Achromatic Options: Available in zero order and achromatic configurations, matched and aligned within cell mounts for optimal performance.

- High Damage Threshold: Designed for applications requiring stability over temperature changes and high damage thresholds, ideal for lasers and infrared sources.

- Versatile Wavelength Range: Standard wavelengths include 355, 532, 632.8, 808, 850, 980, 1064, 1310, 1480, 1550, 1590 nm. Custom wavelengths from 200 to 2300 nm are also available.

Applications

- High Damage Thresholds: Ideal for use with lasers and infrared light sources where high damage thresholds are required.

- Retardation Stability: Maintains retardation stability over temperature changes, ensuring consistent performance.

- Polarization State Modification: Transmits light and modifies its polarization state without attenuating, deviating, or displacing the beam.

- Quarter and Half Waveplates: Offers quarter and half wave options for different polarization effects.

- Customizable Retardance: Allows for any degree of retardance at any wavelength for which quartz is transparent.

- Precision Manufacturing: Fabrication starts from quartz materials with axes oriented within a few arcminutes, polished to a laser-quality finish.

Frequently Asked Questions

What is an Achromatic Waveplate?

What is the working wavelength of a single material waveplate?

What is the damage threshold of a High Power Waveplate?

What is a Dual Wavelength Waveplate used for?

What is the thickness tolerance of Photonchina's waveplates?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle