Description

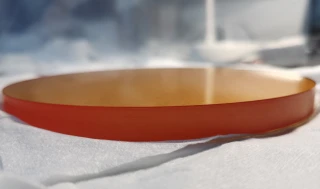

Our high-quality optical components are crafted from a variety of materials, each offering unique properties suitable for diverse applications. These materials include Zinc Selenide (ZnSe), Zinc Sulfide (ZnS), Germanium (Ge), Silicon, Calcium Fluoride (CaF2), Sapphire, Fused Silica, SF, and BK7. Each material is engineered with precision, featuring a diameter tolerance of +0.0''/-0.010'' and a thickness tolerance of ±.010''. This ensures that our components meet stringent specifications for optimal performance.

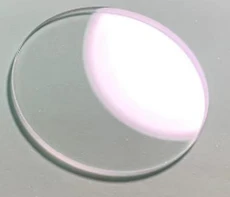

Our optical components boast a wedge surface figure of less than 3 arc minutes and a superior surface quality of 40/20 or better, depending on the material. These specifications ensure minimal optical distortion and high clarity, critical for precision optics. Furthermore, with a high surface quality and a coating that enhances transmittance to over 85%, these components are designed to deliver exceptional optical performance. The chamfering, ranging from .01'' to .03'' at 45°, adds durability and safety to the edges, making them suitable for various optical setups.

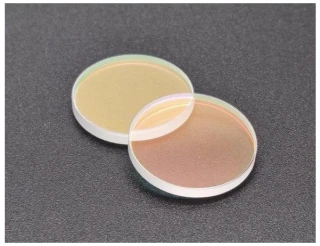

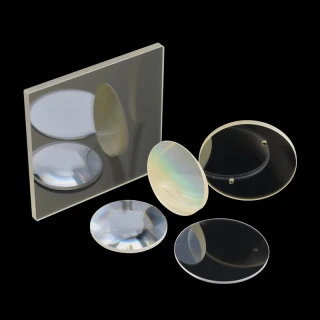

Whether you require spherical lenses, cylindrical lenses, or flats/plano components, our offerings are designed to meet your specific needs. Our narrowband and broadband coatings cater to a wide range of wavelengths, from the ultraviolet (UV) and visible (VIS) spectrums to the infrared (IR) range, ensuring versatility and adaptability in diverse environments. The narrowband coatings provide reflectance (R) of ≤0.25% to ≤0.5%, while broadband coatings offer average reflectance (Ra) of ≤0.5% to ≤1.5%. For laserline applications, the coatings achieve reflectance of ≥99.5% to ≥99.7%, ensuring maximum efficiency and performance in demanding optical systems.

Please note that the specifications provided are intended for reference only and may vary based on dimensions and specific customer requirements. Our team is committed to delivering customized solutions that meet your exact optical needs, ensuring precision and reliability in every component.

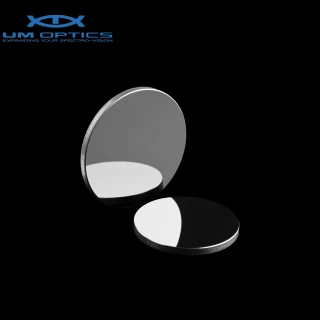

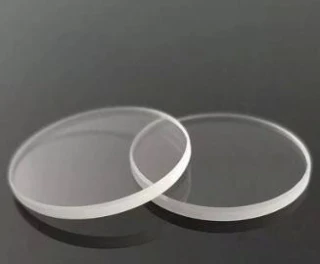

RMI Plane Windows - BK7-UVFS-FS

Specifications

| Substrate Material: | N-BK7, Fused Silica, UV Grade Fused Silica |

|---|---|

| Antireflection Coating: | Coated, Uncoated |

| Surface Quality: | 10-5 scratch-dig |

| Surface Flatness: | lambda/20 |

| Diameter And Thickness: | Custom |

Features

- Material Options: ZnSe, ZnS, Ge, Silicon, CaF2, Sapphire, Fused Silica, SF, BK7

- Diameter Tolerance: +0.0''/-.010''

- Thickness Tolerance: ±.010''

- Wedge Surface Figure: < 3 arc min

- Surface Quality: 40/20 for ZnSe, ZnS, Ge, Silicon; 20/10 for CaF2, Sapphire; 10/5 for Fused Silica, SF, BK7

- Surface Figure: λ/40 @ 10.6µm for ZnSe, ZnS, Ge, Silicon; λ/4 for CaF2, Sapphire; λ/10 for Fused Silica, SF, BK7

- CA Chamfer: .01'' - .03'' @ 45° for standard options, .02'' @ 45° for specific configurations

- Transmittance: > 85%

- Lens Types: Spherical Lens, Cylindrical Lens, Flats/Plano

Applications

- Beam Steering and Deviation: Ideal for controlled beam displacement and optical path adjustment.

- Interferometry Systems: Ensures precise wavefront manipulation in interferometric setups.

- Laser Alignment and Calibration: Supports accurate laser system alignment and calibration procedures.

- Spectroscopy and Metrology: Suitable for high-precision optical measurement applications.

- Polarizing Assemblies: Integrates into polarization-sensitive optical systems for controlled beam handling.

Frequently Asked Questions

What factors should be considered when selecting window substrates?

What are RMI Plane Windows used for?

What shapes and sizes are available for Plane Windows?

What are the units for UV/VIS/NIR substrates?

What are the units for IR substrates?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle