Description

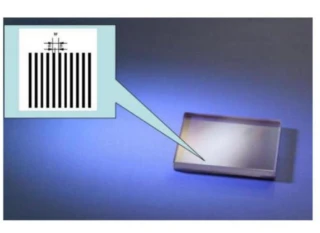

HORIBA Jobin Yvon has produced a wide range of ruled master gratings from which we manufacture high precision replicas. Dimensions of our high-precision replica gratings typically range from 25x25 mm up to 120x140 mm.

Ruled Plane Grating 510 50

Specifications

| Groove Density: | 300 l/mm |

|---|---|

| Blaze Wavelength: | 250 nm |

| Substrate Material: | Custom, Metallic, ULE, Zerodur, Fused Silica, NBK7, Pyrex |

| Dimension (Length): | 110 mm |

| Dimension (Height): | 110 mm |

| Dimension (Thickness): | 16 mm |

Applications

Monochromators and Spectrographs

Raman Spectrometers

Spectroscopy

Beam isolation

Frequently Asked Questions

What is the efficiency performance of the ruled plane gratings?

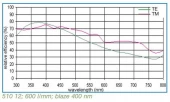

The efficiency performance of the ruled plane gratings varies depending on the specific grating. The datasheet provides efficiency curves for three different gratings: 510 21; 300 l/mm; blaze 2 µm, 510 37; 75 l/mm; 5-16 µm, and 510 12; 600 l/mm; blaze 400 nm. These efficiency curves are absolute theoretical efficiencies, calculated using rigorous electromagnetic theory, taking into account the true groove profiles of manufactured gratings measured with an atomic force microscope (AFM).

What materials are used for the custom master ruled gratings for CO2 lasers?

The custom master ruled gratings for CO2 lasers are optimized at 10.6 micron and made with a ruling density of 150 l/mm. The coating is gold and the substrate material is stainless steel with a substrate dimension of 25 mm diameter on 25x25 mm. The absolute efficiency is higher than 95% for TM polarization over 9 to 11 µm wavelength range.

What is the blaze angle of the ruled plane gratings?

The blaze angle of the ruled plane gratings is given by the formula 2a sinα= kλB, where a is the groove spacing, k is the diffraction order (usually k=1) and λB is the blaze wavelength (in Littrow configuration). The blaze angle is indicated on page 35 of the datasheet.

What are ruled plane gratings?

Ruled plane gratings are high-precision replicas of ruled master gratings produced by HORIBA Jobin Yvon. They are used in various applications such as monochromators, spectrographs, Raman spectrometers, and beam isolation.

What are the dimensions of the high-precision replica gratings?

The dimensions of the high-precision replica gratings typically range from 25x25 mm up to 120x140 mm.

Similar Products

Diffraction Amplitude Gratings

Coligh Optics Technology Co.,ltd

2 µm Multi-Layer Dielectric Reflection Gratings, 98% Efficiency

Gitterwerk GmbH

Reflection Gratings for 1030 nm

Gitterwerk GmbH

Reflection Gratings for 1064 nm

Gitterwerk GmbH

Transmission Gratings for 920 nm

Gitterwerk GmbH

Transmission Gratings for UV

Gitterwerk GmbH

Reflective Ruled Diffraction Grating

Albrighter Technology Co.,Ltd.

Transmission Gratings for 2 μm

Gitterwerk GmbH

Transmission Gratings for 1550 nm

Gitterwerk GmbH

Transmission Gratings for NIR

Gitterwerk GmbH

Transmission Gratings for 1064 nm

Gitterwerk GmbH

Transmission Gratings for 1030 nm

Gitterwerk GmbH

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle