Description

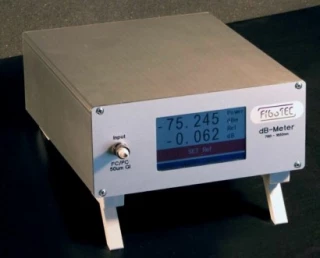

Gentec-EO introduces the P-LINK series, a line of sophisticated PC-based power monitors, available in both 1 and 4 channel configurations. Engineered for precision and flexibility, the P-LINK monitors are the perfect tools for a wide array of industrial light measurement tasks. With their compact and adaptable design, they seamlessly integrate into various settings, offering unparalleled ease of use.

Designed to cater to the diverse needs of professionals, the P-LINK series is fully compatible with thermopiles and photo detectors, ensuring broad application coverage. Whether for intricate scientific research, advanced manufacturing processes, or quality control assessments, the P-LINK monitors provide accurate, real-time data, making them indispensable in any setting where light measurement is critical.

Gentec-EO - 4 Channel Power Monitors- P-LINK-4-Ethernet

Specifications

| Detector Compatibility: | Photodiode, Thermopile |

|---|---|

| Min Measurable Energy: | Not Applicable |

| Max Measurable Energy: | Not Applicable |

| Min Measurable Power: | <10 pW |

| Max Measurable Power: | <10 W |

| Energy Monitor Accuracy: | Not Applicable |

| Power Monitor Accuracy: | <2% |

| Thermopile Power Range: | 3uW - 30kW |

Features

- Broad Detector Compatibility: The P-LINK series is adept at reading all power detector types, including thermopiles and photo detectors from the PH Series, ensuring wide applicability.

- PC Integration: These monitors are designed for seamless PC connectivity, coming with dedicated software that provides a comprehensive platform for data analysis and monitoring.

- Multi-Channel Monitoring: The series offers the flexibility of 1 or 4 channel options, allowing for simultaneous monitoring of multiple sources or parameters.

- Full User Control: Equipped with serial commands, the P-LINK series gives users complete control over their monitoring and data analysis tasks.

- Advanced Statistical Functions: Features real-time statistical functions like Max, Min, Average, and more, with the P-LINK-4 also offering High Low Alarm and Post-Analysis Mode for in-depth data analysis.

- Versatile Connectivity: Users can choose between USB, RS-232, or Ethernet (4-channel version only) connectivity, with the USB version being conveniently port-powered.

- Real-Time Data Display: Offers real-time data display in various formats, including histogram and statistics, providing instant insights into power metrics.

Applications

- Laser System Testing and Calibration: Ideal for use in laser system manufacturing and maintenance, where precise power measurements are crucial for calibration and testing.

- Research and Development: An invaluable tool in R&D settings, where accurate and real-time monitoring of laser power can significantly impact experimental outcomes.

- Industrial Process Monitoring: Suitable for monitoring laser-based processes in industries, such as cutting, welding, and engraving, ensuring optimal operation and output.

- Quality Assurance: Essential for QA processes in industries that rely on precise laser power settings to maintain product quality and safety standards.

- Photonics and Optoelectronics: Supports photonics research and development, where precise control and measurement of light sources are critical.

- Educational Purposes: An excellent educational tool for universities and technical institutes, allowing students to gain hands-on experience with laser power measurements.

Frequently Asked Questions

What is the Gentec-EO 4 Channel Power Monitor?

What are the features of the Gentec-EO 4 Channel Power Monitor?

What types of power detectors can the Gentec-EO 4 Channel Power Monitor read?

What is the difference between the 1 and 4 channel options of the Gentec-EO 4 Channel Power Monitor?

What communication ports are available for the Gentec-EO 4 Channel Power Monitor?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle