Description

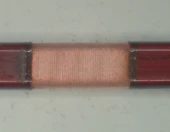

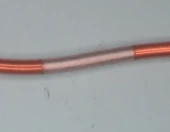

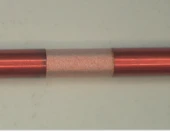

Whether you’re processing magnet wire, micro coax or rigid coax, the Gemini-4E is the versatile wire processor that will make your production line smoother. The easy-to-use, recipe controlled system requires minimal training with your operators while ensuring consistent results in seconds. With the generous processing area, the Gemini-4E can process lengths of up to 100mm (4″) in a single step.

No more heavy-duty machinery that takes up vital space in your factory. The benchtop Gemini-4E will slot straight into your production line on any bench wherever it is required as either a stand alone machine, or an integrated system.

By utilizing the power of laser processing you’ll be able to achieve high quality results, without having to rely on operator capability. It makes wire processing an easy task that can be easily completed in a matter of seconds.

While lasers can process most wire and cable materials, we recommend producing a small sample of wire for testing to ensure processing suitability.

Gemini 4E Laser Wire Stripper

Specifications

| Wire Coating Type: | Polyimide, Other |

|---|---|

| Max Strip Length: | 100 mm |

| Max Wire Diameter: | 2 mm |

| Processing Speed: | 2000 mm/sec |

| Fume Extraction Unit: | Unspecified |

| Laser Type: | Fiber |

| Laser Safety Class: | Class 4 |

Features

- Strip any pattern, including angled lines or curves to perfectly match your cable layout

- Benchtop system

- Z axis Focus control

- Recipe controlled

- Simple recipe backup

- Simple programming

- Multi-languages supported

- Integrated Touchscreen

- Controlled via integrated PC with Laser Wire Software

- On board diagnostics

Applications

- Enamels,

- Polyimide,

- PEI,

- PAI

- Foils

- Micro-coax shields

Frequently Asked Questions

Who designs the bespoke fixture plates?

How do I prevent unauthorized access to the machine?

Do I need fume extraction?

How do I order?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle