Description

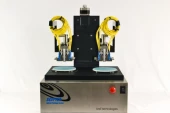

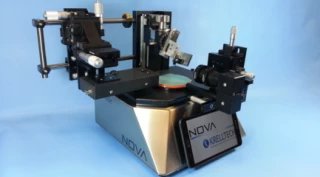

Scepter X2™ Automated Connector Polishing System is a revolutionary advancement in the field of optical polishing, designed to enhance efficiency and precision. This state-of-the-art system introduces dual position optical polishing, effectively doubling the capacity of the standard Scepter™. With its innovative design, the Scepter X2™ ensures that your polishing processes are not only faster but also more reliable, meeting the highest industry standards.

The system is equipped with an external PC control with Microfeed™, allowing for precise adjustments and control over the polishing process. This feature, combined with independent suspension workholders, ensures that each connector is polished to perfection. The independent suspension workholders provide controlled pressure and uniform contact with the polishing surface, which is crucial for achieving consistent results. This technology supports all industry-standard connectors, MIL-termini, and ferrules, making it a versatile choice for various applications.

One of the standout features of the Scepter X2™ is its ability to perform air polishing within the machine, a process that maximizes film life while maintaining high-quality finishes. The system is Telcordia compliant, ensuring that it meets rigorous industry standards for performance and reliability. The intuitive user interface simplifies the creation of polishing programs, allowing users to easily input parameters such as cycle time, pressure, and speed settings for all connector types and desired surface geometries.

The Scepter X2™ is designed to deliver exceptional polishing performance, with an apex offset of less than 50 microns maximum and typically less than 15 microns. Its optical performance is equally impressive, with back reflection of less than -60 dB for UPC and less than -65 dB for APC, and an insertion loss of less than 0.25 dB, typical. These specifications ensure that the Scepter X2™ not only meets but exceeds industry expectations, providing a reliable solution for high-precision optical polishing needs.

https://krelltech.com/polishers/detail/scepter-x2-dual-position-connector-polish-v2er/

Scepter X2 Dual Position Connector Polisher

Specifications

| Fiber Diameter Range: | 1 – 1 um |

|---|---|

| Objects Polished: | Fiber Connectors, Waveguides, Bare Fiber, Other |

| Inspection Options: | Real-Time Polishing Inspection, In-Line Surface Inspection, Video Signal, Geometry Measurements, Other |

| Apex Offset: | <50 microns, maximum |

| Apex Offset: | <15 microns, typical |

| Radius Of Curvature: | 10-25 mm, 2.5 mm ferrules |

| Radius Of Curvature: | 7-20 mm, 1.25 mm ferrules |

| Radius Of Curvature: | 5-12 mm, APC ferrules |

| Undercut/Protrusion: | 0 to -100 nm |

| Back Reflection: | < -60 dB, UPC |

| Back Reflection: | < -65 dB, APC |

| Insertion Loss: | < 0.25 dB, typical |

| Connector Capacity: | 24 connectors using Independent Suspension workholders |

| Connector Capacity: | 58 connectors with high capacity workholders |

| Process Time: | Approximately 3 to 8 sec/connector |

| Polishing Pressure: | Programmable, sub-micron, automated, linear displacement |

| Polishing Speed: | Program selectable |

| Cycling Timing: | Program selectable |

| Polishing Motion: | Random orbital |

Features

- Dual-Position Polishing: Doubles capacity compared to the standard Scepter™ system.

- Independent Suspension Workholders: Ensures uniform contact and maximized polishing film life.

- External PC Control with Microfeed™: Provides precise adjustment of polishing parameters.

- Universal Connector Support: Compatible with all industry-standard, MIL-spec, and custom connectors/termini.

- Telcordia-Compliant Results: Meets and exceeds industry standards for apex offset, radius of curvature, and surface geometry.

- Programmable Automation: Selectable cycle time, pressure, speed, and orbital motion for process optimization.

https://krelltech.com/polishers/detail/scepter-x2-dual-position-connector-polish-v2er/

Applications

- High-Volume Fiber Optic Manufacturing: Increases throughput with dual-position and high-capacity workholders.

- Telecommunication Networks: Delivers consistent, Telcordia-compliant optical performance for reliable network operation.

- Military and Aerospace Fiber Systems: Supports MIL-spec connectors for mission-critical optical applications.

- Research and Development Labs: Enables precision polishing with programmable parameters for custom optical experiments.

https://krelltech.com/polishers/detail/scepter-x2-dual-position-connector-polish-v2er/

Frequently Asked Questions

What is the capacity of the Scepter X2 Dual Position Connector Polisher?

How many connectors can be processed simultaneously with the Scepter X2 Dual Position Connector Polisher?

Does the Scepter X2 Dual Position Connector Polisher support all industry standard connectors?

What are the optical performance standards of the Scepter X2 Dual Position Connector Polisher?

What is the polishing time for each connector using the Scepter X2 Dual Position Connector Polisher?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle