Description

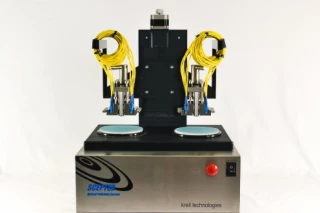

Experience unparalleled flexibility in optical surface processing with the NOVA™ Automated & Multi-Configurable Polishing System. This innovative system by KrellTech combines the proven performance of industry-leading polishers like Scepter, Trig, and FLex into a single, cost-effective solution. Designed to support a wide range of polishing applications, NOVA™ is ideal for connectors, waveguides, bare fibers, and custom components. Whether you're working on R&D projects, high-volume production, or field installations in harsh environments, NOVA™ is scalable to meet your needs.

The NOVA™ system features KrellTech’s patented independent suspension at each connector position, ensuring controlled pressure and uniform contact. This, combined with the Microfeed™ fixture advancement, allows for connector “air-polishing” and epoxy removal directly within the machine. Each position is optically aligned for optimal polish geometry using KrellTech’s patented process and calibration mechanism, allowing for a mix-and-match of connector types in a single fixture.

NOVA™ offers remarkable versatility, supporting the polishing of various photonic components. Quick change-out of workholder fixtures enables processing capabilities for waveguides, optical chips, PLCs, lenses, and fiber arrays. The unique holding mechanism of the workholders can secure a wide range of component dimensions, with adjustable polishing angles and the option for custom fixtures for specialized applications. Specialized workholders and adapters allow for the polishing of bare fiber at variable angles, accommodating fiber types from standard singlemode to PM, sapphire, and PCF, and shaping them into wedge and chisel tip forms.

The system's adaptability is further enhanced by the ability to quickly swap adapters, allowing for the polishing of fiber diameters ranging from 80um to over 3mm. Optional video inspection systems are available to monitor the polishing process and inspect the polished surface directly within the NOVA™ system, ensuring precision and quality in every application.

https://krelltech.com/polishers/detail/nova-waveguide-array-polishing-system/

NOVA Waveguide And Array Polishing System

Specifications

| Fiber Diameter Range: | 1 – 1 um |

|---|---|

| Objects Polished: | Fiber Connectors, Waveguides, Bare Fiber |

| Inspection Options: | Real-Time Polishing Inspection, Video Signal |

| Connector Support: | All industry standard connectors, Mil-spec termini and ferrules, UPC & APC geometries |

| Capacity: | Up to 8 components |

| Apex Offset: | <50 microns, maximum; <15 microns, typical |

| Radius Of Curvature: | 10-25 mm, 2.5 mm ferrules; 7-20 mm, 1.25 mm ferrules; 5-12 mm, APC ferrules |

| Protrusion/Undercut: | 50nm to -120 nm |

| Back Reflection: | < -60 dB, UPC; < -65 dB, APC |

| Insertion Loss: | < 0.25 dB, typical |

| Process Time: | Approximately 15 sec/connector |

Features

- Automated & Multi-Configurable Polishing System: NOVA™ offers maximum flexibility for optical surface processing, integrating proven performance features from industry-leading polishers.

- Precision Optical Polishing: Achieve high-quality finishes with precise control over polishing parameters.

- Tablet Control with Microfeed™: Easy-to-use tablet interface with Microfeed™ fixture advancement for enhanced control.

- Supports All Industry Standard Connectors: Compatible with MIL-termini, ferrules, and more, ensuring broad application support.

- Air Polishing in Machine: Perform connector air-polishing and epoxy removal directly within the machine.

- Telcordia Compliant: Meets industry standards for reliability and performance.

- Interchangeable Fixtures: Quickly swap workholder fixtures to process waveguides, bare fibers, optical chips, PLCs, lenses, and fiber arrays.

- Independent Suspension Workholders: Patented design ensures controlled pressure and uniform contact for optimal polishing results.

- Optical Alignment for Optimal Geometry: Each position is optically aligned using KrellTech’s patented process for superior polish geometry.

- Adjustable Polishing Angle: Customize the polishing angle with unique holding mechanisms for a wide range of component dimensions.

- Variable Angle Bare Fiber Polishing: Specialized workholders and adapters allow for polishing at various angles.

- Wide Range of Fiber Types Supported: Process fibers from standard singlemode to PM, sapphire, and PCF into wedge and chisel tip shapes.

- Quick Adapter Swap-Out: Easily polish fiber diameters from 80um to >3mm.

- Optional Video Inspection Systems: Monitor the polishing process and inspect polished surfaces directly in NOVA.

https://krelltech.com/polishers/detail/nova-waveguide-array-polishing-system/

Applications

- Optical Communication Systems: Reliable connector and fiber finishing for telecom networks.

- Fiber Optic R&D and Prototyping: Ideal for research labs requiring precise polishing versatility.

- High-Volume Manufacturing: Scalable system for consistent mass production.

- Field Deployment & Harsh Environments: Rugged design for on-site polishing and repair.

- Photonic Device Processing: Supports waveguides, PLCs, lenses, and custom optical components.

- Specialty Fiber Applications: Enables polishing of PM, PCF, sapphire, and chalcogenide fibers.

https://krelltech.com/polishers/detail/nova-waveguide-array-polishing-system/

Frequently Asked Questions

What can the NOVA Waveguide And Array Polishing System be used for?

Can the polished endface angles be adjusted?

Is the polishing process manual or automated?

Does the NOVA system have a video inspection feature?

What types of components can be polished with the NOVA system?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle