Description

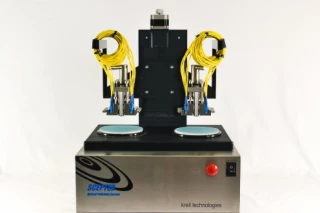

Introducing the FLex™ Waveguide Polisher, a cutting-edge solution from Krell Technologies, Inc., designed to revolutionize the processing of waveguides, planar lightwave circuits (PLCs), optical chips, and fiber arrays. This innovative device is engineered to deliver cost-effective and efficient polishing, ensuring high-quality results for a wide range of optical components.

The FLex™ Waveguide Polisher is equipped with a universal carrier that accommodates various component dimensions, thanks to its unique “Slide and Guide™” locking mechanism. This feature eliminates the need for wax or epoxy, simplifying the polishing process and enhancing operational efficiency. Whether you require flat or angled edge polishing, the FLex™ offers precise control through its precision linear translation and adjustable pressure application, resulting in consistent and repeatable polish yields.

Designed with versatility in mind, the FLex™ allows for adjustable polishing angles, catering to specialized applications with ease. Its compact size and lightweight design make it an ideal choice for both laboratory and field use. The device's user-friendly interface includes a digital cycle timing feature, allowing for customizable polishing durations to meet specific requirements.

For those seeking to expand their capabilities, the FLex™ offers an upgrade option with an optional mounting fixture and fiber adapters, enabling bare fiber polishing applications. This adaptability ensures that the FLex™ Waveguide Polisher remains a valuable asset as your needs evolve.

Experience the future of optical component processing with the FLex™ Waveguide Polisher from Krell Technologies, Inc., where innovation meets precision.

https://krelltech.com/polishers/detail/flex-waveguide-polisher/

FLex Waveguide Polisher

Specifications

| Fiber Diameter Range: | 1 – 1 um |

|---|---|

| Objects Polished: | Fiber Connectors, Waveguides, Bare Fiber, Other |

| Inspection Options: | Real-Time Polishing Inspection, In-Line Surface Inspection, Video Signal, Geometry Measurements, Other |

| Component Dimension Range - Width: | 5mm to 25mm |

| Component Dimension Range - Thickness: | 0.5mm to 5mm |

| Component Dimension Range - Length: | >5mm |

| Polishing Tolerance: | +/-0.3 degree (X/Y axis along edge) |

| Adjustable Polish Angle Range: | 0 deg. (flat) to 45 deg. |

| Polishing Films: | 4 inch diameter |

| Polishing Motion: | Random orbital |

| Power: | AC adapter/9 volt battery |

| Size And Weight: | 7”x 4.5” footprint, 4.5 lbs |

Features

- Processes Waveguides and Optical Chips: The FLex™ Waveguide Polisher is designed for efficient processing of waveguides, planar lightwave circuits (PLCs), optical chips, and fiber arrays.

- Adjustable for Varying Dimensions: Supports a wide range of component dimensions with a width of 5mm to 25mm, thickness of 0.5mm to 5mm, and length greater than 5mm.

- Flat or Angle Polishing: Capable of polishing components with either flat or angled edges, with an adjustable polish angle range from 0 degrees (flat) to 45 degrees.

- Slide and Guide™ Component Holding: Features a unique locking mechanism that secures components without the need for wax or epoxy.

- Precision Polishing Control: Polishing is controlled via precision linear translation and adjustable pressure application, ensuring consistent and repeatable polish yields.

- Polishing Tolerance: Offers a polishing tolerance of +/-0.3 degrees along the X/Y axis.

- Random Orbital Polishing Motion: Utilizes a random orbital motion for effective polishing.

- User Adjustable Timer: Equipped with a digital cycle timing feature for user-adjustable operation.

- Power Options: Operates with an AC adapter or a 9-volt battery for flexibility.

- Compact Size and Lightweight: Features a compact 7”x 4.5” footprint and weighs only 4.5 lbs, making it easy to handle and transport.

- Upgrade Option for Bare Fiber Polishing: An optional mounting fixture with fiber adapters is available to upgrade the FLex™ for bare fiber polishing applications.

https://krelltech.com/polishers/detail/flex-waveguide-polisher/

Applications

- Processes Waveguides and Optical Chips: Designed for the cost-effective processing of waveguides, PLCs, optical chips, and fiber arrays.

- Adjustable for Varying Dimensions: The universal carrier secures a variety of component dimensions using the unique “Slide and Guide™” locking mechanism.

- Flat or Angle Polishing: Components can be polished with either flat or angled edges, with an adjustable polish angle range from 0 degrees (flat) to 45 degrees.

- Slide and Guide™ Component Holding: Secure components without the need for wax or epoxy.

- Bare Fiber Polishing Upgrade Option: An optional mounting fixture with fiber adapters can upgrade FLex™ for bare fiber polishing applications.

- Component Support: Supports waveguides, planar lightwave circuits, optical chips, and fiber arrays.

https://krelltech.com/polishers/detail/flex-waveguide-polisher/

Frequently Asked Questions

What types of components can the FLex Waveguide Polisher polish?

Can the FLex Waveguide Polisher accommodate components of different sizes?

Can the FLex Waveguide Polisher polish components at different angles?

Is there a way to inspect the polished surfaces without removing the waveguide from the machine?

Can the FLex Waveguide Polisher be used for bare fiber polishing?

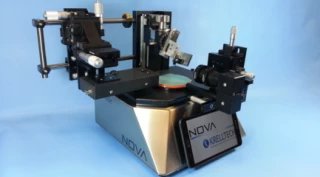

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle