Description

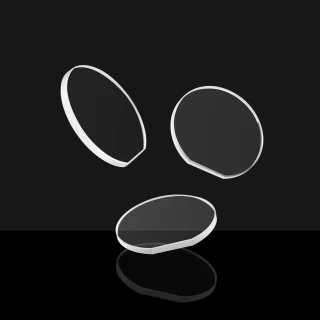

Multiple order waveplate means the retardance of a light path will undergo a certain number of full wavelength shifts in addition to the fractional design retardance. The thickness of multi order waveplate is always around 0.5mm. Compared with zero order waveplate, multi order waveplate is more sensitive to wavelength and temperature changes. However, they are less expensive and widely used in many applications where the increased sensitivities are not critical.

Thickness: 0.3-0.5 mm

High Damage Threshold

Better wavefront and parallelism

Low Cost

RoHS Compliant

Multi Order Waveplate

Specifications

| Waveplate Type: | Multiple Order |

|---|---|

| Material: | Quartz |

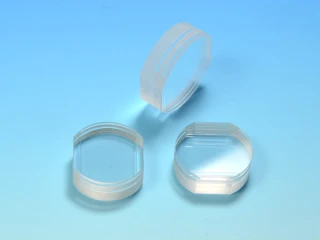

| Mounting: | Mounted, Unmounted |

| Shape: | Round, Square, Rectangle, Custom |

| Size: | 25.4 mm |

| Center Wavelength: | 1064 nm |

| Retardation: | Lambda/2, Lambda/4, Lambda, Other |

| Retardation Accuracy: | +/- Lambda/100, Custom |

| Wavefront Distortion: | <= Lambda/8 |

| Surface Quality (Scratch-Dig): | 20-10 |

Features

Material Crystal Quartz

Dimension Tolerance +0.0/-0.2mm

Wavefront Distortion λ/8@632.8nm

Retardation Tolerance λ/100

Parallelism <1 arc second

Surface Quality 20/10 scratch and dig

Clear Aperture >90% central area

Standard Wave quarter-wave(λ/4), half-wave(λ/2)

AR Coating R<0.25%@central wavelength

Damage Threshold >10J/cm2, 20ns, 20Hz

Frequently Asked Questions

How does a multi order waveplate compare to a zero order waveplate?

What is a multi order waveplate?

What is the damage threshold of a multi order waveplate?

What is the surface quality of a multi order waveplate?

What is the thickness of a multi order waveplate?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle