Description

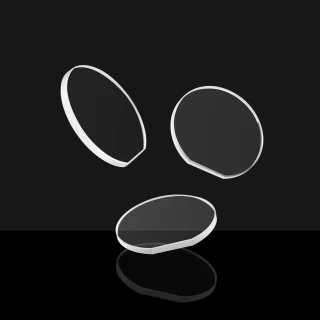

Experience unparalleled precision and reliability with our expertly crafted quartz waveplates. Designed for advanced optical applications, these waveplates are meticulously manufactured to ensure exceptional performance. The use of high-quality quartz material ensures durability and stability, making them a preferred choice for professionals seeking excellence in optical components.

Our waveplates are engineered with a focus on minimizing imperfections, featuring a scratch and dig rating of 40/20~10/5. This ensures a pristine surface quality, essential for maintaining the integrity of transmitted light. Additionally, the transmitted wavefront distortion ranges from λ/2 to λ/8, providing superior optical clarity and precision.

Precision alignment is critical in optical systems, and our waveplates offer exceptional parallelism ranging from 3 arc seconds to 1 arc second. With a retardation tolerance of less than λ/300, these waveplates deliver highly accurate phase retardation, crucial for demanding applications. Furthermore, they are AR coated at a custom wavelength, enhancing their performance by reducing reflection losses.

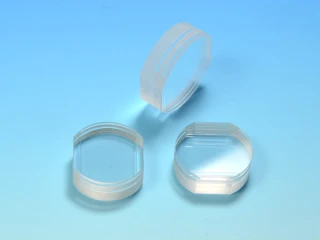

Choosing the right waveplate involves several key parameters: wavelength, retardance type (such as half-wave or quarter-wave), and the order of the waveplate. Our selection includes various orders, with low order and several zero order options such as Cemented Zero Order, True Zero Order, Air Spaced Zero Order, and Optical Contacted Zero Order. Zero order waveplates offer broader wavelength, temperature, and angle bandwidths compared to low order waveplates.

Among the zero order types, True Zero Order and Air Spaced, as well as Optical Contacted types, boast a large damage threshold, making them suitable for high-power applications. However, True Zero and Optical Contacted types require more complex manufacturing processes. The Cemented type, while easier to produce, has a lower damage threshold, making it ideal for less demanding environments.

Low Order Waveplate

Specifications

| Waveplate Type: | Multiple Order |

|---|---|

| Material: | Quartz |

| Mounting: | Mounted |

| Shape: | Custom |

| Size: | 12.7 mm |

| Center Wavelength: | 633 nm |

| Retardation: | Lambda/4 |

| Retardation Accuracy: | +/- Lambda/300 |

| Wavefront Distortion: | <= Lambda/8 |

| Surface Quality (Scratch-Dig): | 20-10 |

| Parallelism: | 1 arc Sec |

| Coating: | AR@633nm R<0.2% |

Features

- Precision Quartz Construction: Ensures excellent durability and optical performance

- Multiple Order Options: Available in Low Order and five Zero Order types

- High Surface Quality: Scratch-dig options from 40/20 to 10/5 for superior finish

- High Retardation Accuracy: Tolerance better than λ/300 for phase-sensitive applications

- Low Wavefront Distortion: Up to λ/8 for minimal beam degradation

- Excellent Parallelism: As low as 1 arc second for tight optical alignment

- Custom AR Coatings: Optimized for user-specified operating wavelengths

- High Damage Threshold (select types): Especially True Zero and Optical Contacted designs

Applications

- Laser Polarization Control: Adjust or rotate polarization states in precision laser systems

- Optical Communication: Maintain or manipulate polarization in fiber-based systems

- Quantum Optics: Enable accurate polarization manipulation in entanglement experiments

- Microscopy & Imaging: Improve contrast and polarization-based imaging fidelity

- Spectroscopy Systems: Enhance control over input/output light polarization

- OEM & R&D Integration: Ideal for integration into custom optical setups and scientific instruments

Frequently Asked Questions

What is a waveplate or retarder?

What are waveplates made of?

What are the important parameters to know when ordering waveplates?

What is the difference between low order and zero order waveplates?

What are the applications of waveplates?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle