Description

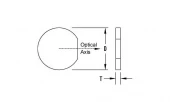

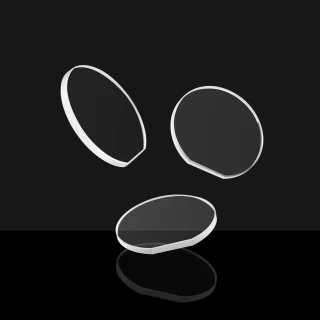

Multi-Order Waveplates are essential optical components used in the manipulation of polarized light. These waveplates are crafted from a single plate of either Crystalline Quartz or Sapphire, which ensures high precision and reliability in their performance. The primary function of multi-order waveplates is to alter the polarization state of light, making them crucial in various optical systems and experiments. They are specifically designed to provide optimal performance at their designated wavelength due to the rapid variation of retardation with wavelength.

The construction of these waveplates involves meticulous attention to detail, with a focus on achieving the highest quality standards. The surface quality of the waveplates is maintained at an exceptional level, ensuring minimal imperfections and maximum efficiency in light transmission. The thickness of the plate is carefully controlled, as it plays a significant role in the retardation process. Additionally, these waveplates are slightly temperature-dependent, which is a consideration during their application in environments with varying thermal conditions.

At Rocky Mountain Instrument Co., we pride ourselves on our collaborative approach with clients, working closely with them from the early stages of development. Our goal is to transform prototype concepts into efficient and manufacturable solutions, addressing even the most technically challenging requirements. Our multi-order waveplates are a testament to our commitment to quality and innovation in the field of optics.

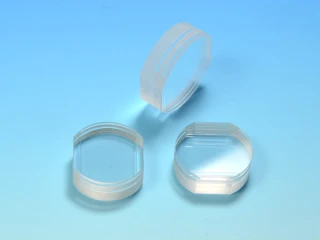

Crystalline Quartz Multi-Order Waveplate

Specifications

| Waveplate Type: | Multiple Order |

|---|---|

| Material: | Quartz |

| Mounting: | Unmounted |

| Shape: | Round, Custom |

| Center Wavelength: | 633 nm |

| Retardation: | Lambda/2, Lambda/4 |

| Retardation Accuracy: | +/- Lambda/100, +/- Lambda/600, +/- Lambda/500, +/- Lambda/400, +/- Lambda/300, +/- Lambda/200 |

| Wavefront Distortion: | <= Lambda/10 |

| Surface Quality (Scratch-Dig): | 10-5 |

| Thickness And Diameter: | Custom |

Features

- Material: Made from high-quality Crystalline Quartz.

- Angle of Incidence: 0° for optimal performance.

- Construction: Single multiple order plate for precise light manipulation.

- Transmitted Wavefront: λ/10 at 633nm ensures superior wavefront quality.

- Surface Quality: 10 – 5 on both surfaces for exceptional optical clarity.

- Diameter Tolerance: +0.000, -0.25mm for precise fitting in optical systems.

- Thickness: Nominal 2.0 mm for standard applications.

- Wedge: ≤ 0.5 arc seconds to minimize beam deviation.

- Bevels: Minimum safety bevel for user protection and durability.

- Clear Aperture: Central 85% of diameter for maximum effective area.

- Anti-Reflection Coating: R ≤ 0.25% per surface to reduce reflection losses.

- Retardation Tolerance: λ/100 - λ/600 for precise phase control.

Applications

- Fixed-Wavelength Laser Systems: Precise polarization control in single-wavelength laser applications

- Optical Instrumentation: Used for polarization manipulation in optical assemblies

- Polarization Analysis: Ideal for laboratory experiments requiring defined retardation

- OEM Optical Systems: Cost-effective polarization components for integrated system designs

- Microscopy and Imaging: Enhances polarization control in advanced imaging setups

Frequently Asked Questions

What is the difference between Quarter Waveplates and Half Waveplates?

What are Multi-Order Waveplates made of?

What is the Surface Quality of Multi-Order Waveplates?

What are waveplates used for?

What is the Retardation Tolerance of Multi-Order Waveplates?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle