Description

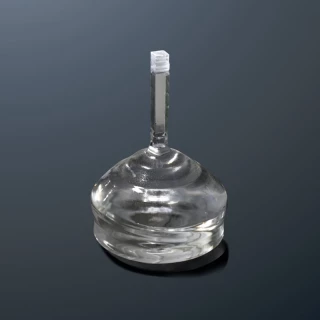

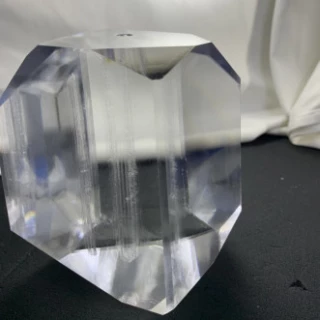

Calcium fluoride (CaF2) crystals with high hardness, strong resistance to mechanical shock and thermal shock is good transmittance in UV, visible and infrared fields. Calcium fluoride (CaF2) crystals are widely used in scientific and technological fields such as lasers, infrared optics, UV optics and high-energy detectors. Especially they have good optical properties in the UV band and they are the known optical crystals in the UV cut-off band.

Optical Crystal Calcium Fluoride Crystal CaF2 Blanks

Specifications

| Type Of Crystal: | Calcium Fluoride (CaF2) |

|---|---|

| Crystal Diameter Range: | 3 – 520 mm |

| Crystal Length Range: | 3 – 520 mm |

| Wavelength Range: | 130 – 10000 nm |

| Type Of Crystal: | calcium fluoride(CaF2) |

| Crystal Diameter: | 520mm |

| Material Grade: | UM-DUV, UM-UV, UM-IR |

| Wavelength Range: | 0.13-10μm |

| Crystal Structure: | Monocrystalline/Polycrystalline |

| Orientation: | <111>,<110>,<100> |

Features

- Ultra-High Purity & Homogeneity: In-house growth enables strict control over raw material quality, achieving ≥99.99999% purity with minimal impurities . This ensures uniform optical properties across the entire crystal, avoiding beam distortion in high-precision applications

- Broad Spectral Transmittance: Excellent transparency from deep UV to mid-IR , with zero intrinsic birefringence—ideal for multi-spectral optical systems requiring consistent light transmission

- Superior Thermal Stability: Low thermal expansion coefficient (1.89×10⁻⁶/°C) and high melting point (1418°C), resisting thermal shock and deformation even in extreme temperature fluctuations (-50°C to 300°C)

- High Laser Damage Threshold (LIDT): Minimal optical absorption, especially in UV and visible ranges, providing LIDT ≥15 J/cm² (1064 nm, 10 ns pulses) for unprocessed crystals. Suitable for high-power excimer lasers (193 nm/248 nm) and DUV lithography systems

- Chemical Inertness & Durability: Non-hygroscopic (no moisture absorption) and resistant to most acids (except strong alkalis), ensuring long-term stability in harsh laboratory, industrial, and space environments.\

Applications

- Optical Component Fabrication: Core raw material for manufacturing CaF₂ windows, lens, prisms, and beamsplitters used in UV-IR optical systems

- Semiconductor Lithography: Critical for DUV lithography tools (193 nm excimer lasers) to produce advanced microchips, leveraging high transmittance and low birefringence

- Scientific Research: Applied in synchrotron radiation experiments, vacuum UV spectroscopy, high-energy physics detectors, and laser fusion research requiring ultra-pure optical materials

- Aerospace & Defense: Used in space-based IR telescopes, missile guidance systems, and satellite optical sensors—withstanding extreme vacuum, temperature, and radiation conditions

- Medical & Industrial Lasers: Raw material for optical components in UV laser surgery tools, laser micromachining equipment, and FTIR spectrometers

Frequently Asked Questions

Why is calcium fluoride monocrystalline material more expensive than polycrystalline? What is the main difference?

Single crystal calcium fluoride has no obvious crystal boundary line. It has higher production cost, better consistency and uniformity, and is suitable for complete sets of lenses, coated products, high power laser products, microscopes and cameras,etc.

Polycrystalline calcium fluoride crystals are mainly used in protective windows, uncoated products, gas analysis sensing, thermal imaging or products with no requirement for imaging quality.

What is the main difference between infrared calcium fluoride and ultraviolet calcium fluoride crystals?

nfrared calcium fluoride crystals are mainly made of natural fluorite with low price and have obvious absorption at 205nm and 306nm. UV calcium fluoride crystals are mostly made of high purity chemical synthesis materials, which control cerium and lead absorption in crystal growth and have no absorption at 200-400nm. The trend of transmittance curve is more stable.

Will polycrystalline calcium fluoride have a lower transmittance than monocrystalline?

Because of the isotropic of calcium fluoride crystallsmaterials, there is generally no major difference in transmittance between polycrystalline and monocrystalline.

What advantages does your in-house grown CaF₂ crystal have compared to externally sourced ones?

Our self-grown CaF₂ crystals eliminate third-party supply chain risks, allowing us to strictly control purity, defect density, and growth parameters to meet custom performance requirements. Additionally, cutting out middlemen enables more competitive pricing, faster lead times, and flexible adjustments to production batches.

Similar Products

Factory Supply Optical CZ FZ Silicon Crystal Si Blank

Henan UM Optics Ltd

Factory Supply Optical LiF Lithium Fluoride Crystal

Henan UM Optics Ltd

Optical Magnesium Fluoride MgF2 Crystal

Henan UM Optics Ltd

High Quality BaF2 Barium Fluoride Crystal

Henan UM Optics Ltd

DTGS/DlaTGS – High-Stability Pyroelectric Crystal for Infrared Detection

Crystrong Photonics Technology Co., Ltd

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle