Description

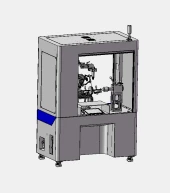

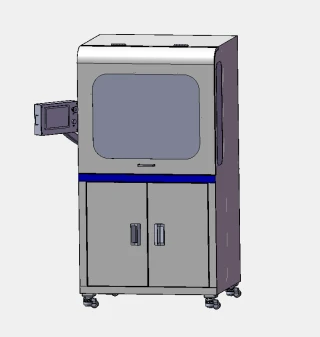

Introducing the Fiber Coil Winding Machine, Model SG-FCM-2.0 from Shanghai Aoshi Control Technology Co., Ltd.

This advanced machine is engineered to wind low-, medium-, and high-precision fiber coils for diverse applications, including hydrophones, optical delay systems, and precision sensing solutions. Supporting versatile winding configurations such as single-pole, quadrupole, and multipole modes, the SG-FCM-2.0 ensures adaptability across a broad spectrum of industrial and research needs. Compatible with fiber diameters ranging from Φ0.06 mm to Φ0.40 mm, it includes customizable accessories tailored to specific diameter requirements.

SG-FCM-2.0 Fiber Coil Winding Machine

Specifications

| Noise Value: | 60 dB |

|---|---|

| Winding Method: | Not Specified |

| Inner Diameter Of Wound Coil: | 12 – 200 mm |

| Height Of Wound Coil: | 1 – 200 mm |

| Spindle Diameter: | 5 – 30 mm |

| Spindle Rotating Speed: | 0 – 200 RPM |

| Spindle Radial Runout: | 0.02 mm |

| Shaft Maximum Stroke: | 200 mm |

| Shaft Positioning Accuracy: | 0.01 mm |

| Optical Fiber Diameter: | 400 um |

| PN: | SG-FCM-2.0 |

| Dimension: | L(1400mm)*W(800mm)*H(1900mm) |

| Weight: | 1000kg |

| Running Noise: | ≤60dB |

| Winding Method: | Single-pole, Quadrupole, Octapole, Sixteen polar |

| Compatible Fiber Coil Inner Diameter: | 12-200mm |

| Height: | 1-200mm |

| Main Axis Diameter: | 5-30mm, Customizable |

| Rotational Speed: | 0~200rpm, adjustable continuously |

| Radial Runout: | ≤0.02mm |

| Fiber Shaft Row Of Fine Trip: | 200mm |

| Repeat Positioning Accuracy: | ≤0.01mm |

| Applicable Fiber Diameter: | 0.04mm~0.40mm |

| Turn Accuracy: | ≤0.02% |

| Meter Error: | ≤0.2% |

| Tension Control - Control: | 2~100g |

| Tension Control - Precision: | ≤0.3g |

| Tension Control - Resolution: | 0.1g |

Features

1. Precision Tension Control System

- Real-time optical fiber tension regulation with ±0.5% accuracy.

- Tension data logging, visualization, and export capabilities for quality assurance.

- Adjustable tension thresholds with automated over-limit shutdown and alerts.

2. Intelligent Process Monitoring

- Integrated meter counter and turn counter for real-time tracking of fiber length and winding layers.

- Vision-assisted alignment system with LED illumination, enabling live observation of fiber placement accuracy.

3. Ergonomic Design & User-Centric Operation

Simplified touchscreen interface for seamless parameter configuration, including:

- Coil core diameter, stack height, fiber diameter, total layers, turns per layer.

- Spindle rotation direction, winding speed (5–200 RPM), tension range (0.1–5.0 N).

- Fiber payout axis calibration, auxiliary wheel settings, and positional limits.

- Multi-directional winding control (forward/reverse, left/right traverse) with pause/resume functionality at any stage.

4. Automated Workflow Optimization

- Programmable multi-layer reverse winding for cross-pattern coil fabrication.

- Layer completion alerts with operator prompts for manual adjustments or tooling changes.

5. Operational Flexibility:

- Manual & Automated Modes: Switch between preset programs or custom workflows.

- Multi-Layer Continuous Winding: Achieve uniform coil density with automated backward winding transitions.

Summary

The SG-FCM-2.0 Fiber Coil Winding Machine by Shanghai Aoshi Control Technology Co., Ltd. combines precision engineering with intuitive operation, making it ideal for applications demanding stringent tolerances in aerospace, defense, and telecommunications. Its industry-leading tension control, real-time analytics, and adaptive winding configurations position it as a benchmark solution for next-generation fiber coil production.

Frequently Asked Questions

What is the name and part number of the product?

What are the main uses of the Fiber Coil Winding Machine?

What winding methods does the machine support?

What are some key features of the Fiber Coil Winding Machine?

What is the size and weight of the machine?

What is the rotational speed range of the machine?

What is the tension control range and precision of the machine?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle