Description

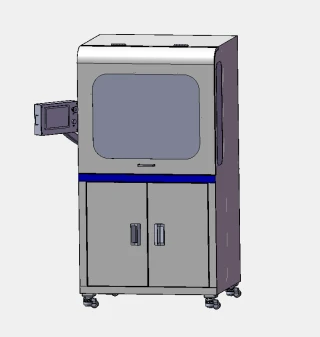

Introducing the Fiber Coil Winding Machine, model ZKRZ-RHJ6.0 from CSRayzer Optical Technology Co.Ltd. This machine is designed to wind low, medium and high-precision fiber coils for a variety of applications, including hydrophones and optical delays. With the ability to support different winding methods such as Sinlgepole, quadrupole, and multipole, this machine is versatile and efficient. The machine can handle fiber diameters from Φ0.06 mm to Φ0.40mm and comes with customized accessories for different fiber diameters.

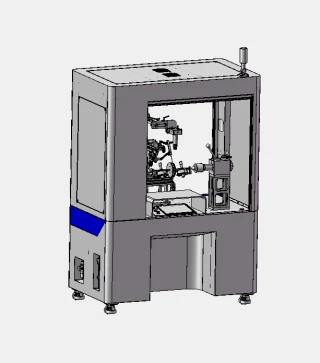

One of the key features of this machine is its tension control system, which allows for precise control of optical fiber tension, and supports the display, saving and reading of tension data. The real-time meter counting and turn counting functions make it easy to keep track of fiber length and number of turns. The visual image observation system with its own lighting system allows for real-time observation of the fiber laying status during the winding process.

The machine is designed with an ergonomic structure that is easy to operate and maintain. The touch screen control allows for easy setting and operation of the winding process, including forward winding, backward winding, left moving, right moving, start, and stop. The touch screen can set relevant processing parameters of the product, including skeleton diameter, coil height, optical fiber diameter, total number of layers, number of turns per layer, fiber discharging shaft parameters, auxiliary wheel parameters, limit alarm, fiber winding speed, tension, spindle rotation direction, fiber laying direction/start/stop coordinate position, spindle rotation angular speed, etc.

The machine has tension control function, tension over-limit stopping, and an alarm function with an adjustable tension range. It can be automatically or manually wound and reversed, while it can be paused and resumed at any position. It also has multi-layer continuous backward winding function. After a single layer winding, it can automatically stop and remind the operator to make relevant adjustments if necessary.

In summary, the Fiber Coil Winding Machine, model ZKRZ-RHJ6.0 is a versatile, efficient, and easy-to-operate machine suitable for winding various fiber coils for a range of applications. Its tension control system, real-time meter counting and turn counting functions, and visual image observation system make it an excellent choice for precision fiber coil winding.

ZKRZ-RHJ6.0 Fiber Coil Winding Machine

Specifications

| Noise Value: | 60 dB |

|---|---|

| Winding Method: | Single Pole, Quadrupole, Octapole, 16-pole |

| Inner Diameter Of Wound Coil: | 16 – 200 mm |

| Height Of Wound Coil: | 1 – 100 mm |

| Spindle Diameter: | 5 – 30 mm |

| Spindle Rotating Speed: | 0 – 100 RPM |

| Spindle Radial Runout: | 0.02 mm |

| Shaft Maximum Stroke: | 200 mm |

| Shaft Positioning Accuracy: | 0.01 mm |

| Optical Fiber Diameter: | 400 um |

| Winding Methods: | Single pole, Quadrupole, Octapole, 16th Pole |

| Radial Runout: | ≤0.02 mm |

| Positioning Accuracy: | ≤0.01 mm |

| Tension Control Range: | 2–30 g |

| Fiber Guide Adjustment: | 360° plane, ±35 mm height |

| Machine Dimensions (L×W×H): | 1300 × 800 × 1900 mm |

| Net Weight: | ≤1000 kg |

Features

- Multiple Winding Modes: Supports single pole, quadrupole, octapole, and 16-pole winding for versatile fiber coil fabrication

- Wide Fiber Diameter Compatibility: Works with fiber diameters from 0.06 mm to 0.40 mm (default: 0.12–0.16 mm)

- Precise Tension Control: Adjustable tension range from 2 to 30 grams with 0.1 g resolution and ≤0.5 g precision

- Touchscreen Interface: User-friendly operation with programmable parameters including coil size, winding speed, and spindle direction

- Real-Time Monitoring: Integrated meter and turn counting with high accuracy (≤0.3% tolerance and ≤0.02% counting error)

- Visual Observation System: Built-in lighting and ≥40x magnification for continuous fiber placement inspection

- Customizable Spindles and Shafts: Supports user-defined dimensions for spindle diameter and fiber discharge shaft

- Flexible Fiber Guiding: 360° adjustable fiber guide wheel plane and ±35 mm height adjustment for optimal routing

- High Precision Motion Control: ≤0.01 mm repeatable positioning accuracy with real-time coordinate tracking

- Ergonomic and Reliable Design: Floor-standing structure with low noise (<60 dB), minimal vibration, and cleanroom compatibility

Applications

- Optical Fiber Coil Manufacturing: Ideal for producing fiber coils for gyroscopes and delay lines

- Hydrophone Assembly: Supports precision winding for underwater acoustic sensing

- Optical Sensing Systems: Used in creating coils for precision fiber optic sensors

- Research & Development: Suitable for lab-based prototyping and testing of winding methods

- Custom Fiber Component Production: Enables controlled winding for specialized applications

Frequently Asked Questions

What is the Fiber Coil Winding Machine used for?

What is the range of fiber diameters supported by the machine?

What types of winding methods does the machine support?

What kind of control system does the machine have?

Does the machine have a tension control system?

What are the applications of the Fiber Coil Winding Machine?

What fiber diameters can the machine handle?

Does the machine support different winding methods?

What are the key features of the machine?

Is the machine easy to operate and maintain?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle