Description

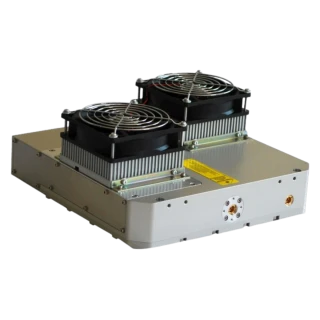

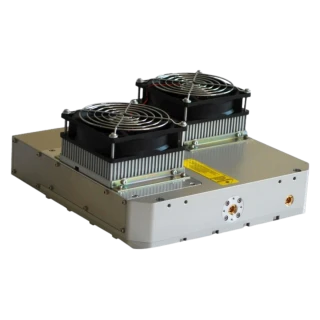

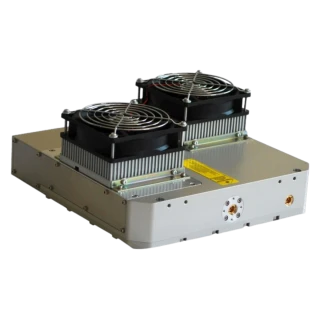

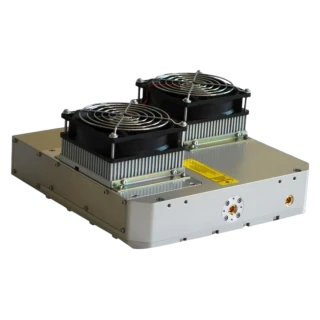

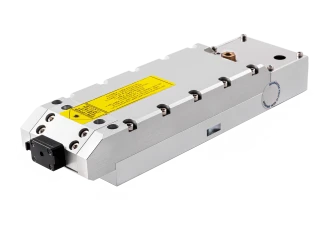

The next product in Advanced Optowave’s ultra short-pulsed laser product line is the AOFemto™ Series. Like the AOPico™ Series, the AOFemto™ is also a diode-pumped solid-state Hybrid master-oscillator power-amplifier, the main difference is the addition of a compressor that enables the AOFemto™ to deliver pulse width less than 800 femtoseconds, with powers up to 15 watts in the IR and 7.5 watts in the green.

Our complete ultra short pulsed laser product line is built on a common platform and we have designed it to use components that we also use in our nanosecond product line, components that have a solid track record for being highly reliable and stable. Because of the common components utilization, we can provide you, the customer, with a much more cost-effective products.

Ultrashort pulse lasers have the unique ability to machine materials with little or no thermal damage, and the ability to machine materials that have not previously been able to be process with lasers.

AOFemto 1030nm 20W DPSS Laser

Specifications

| Avg. Power: | 20 W |

|---|---|

| Wavelength: | 1030 nm |

| Repetition Rate: | 1 – 200 kHz |

| Spatial Mode (M^2): | 1.3 |

| Pulse Duration: | 0.0008 ns |

| Pulse-to-Pulse Stability (RMS): | 2 % |

| Cooling: | Water-to-Water |

| Energy: | 20 µJ |

| Repetition Rate: | Single Shot to 1000 kHz |

| Beam Roundness: | >85 % |

| Beam Diameter: | 2.0 mm |

| Beam Divergence: | <1.3 mRad |

| Beam Divergence: | <0.7 mRad |

| Point Stability: | <20 µrad/ºC |

| Polarization Ratio: | 100:1 Linear, Vertical |

| Polarization Ratio: | 100:1 Linear, Horizontal |

| Pulse-to-Pulse Stability: | <2 % RMS |

| Operational Temperature Range: | 15 to 30 ºC |

| Storage Temperature Range: | -20 to 50 ºC |

| Input Voltage: | 90 to 260 VAC |

Features

- Lowest Cost of Ownership: Designed to offer the most cost-effective solution in the industry.

- Excellent Beam Quality: Achieve superior results with an M2 value of less than 1.3.

- Versatile Wavelength Options: Available in IR, Green, and UV for diverse applications.

- High Average Power: Capable of delivering up to 15W average power for demanding tasks.

- Ultra-Short Pulse Durations: Features pulse durations of less than 800 femtoseconds for precision work.

- Reliable Design: Engineered for high reliability to ensure consistent performance.

- Burst Mode Option: Includes a burst mode for enhanced flexibility in operations.

- Wide Application Range: Suitable for injector drilling, medical device manufacturing, polymer processing, semiconductor processing, and high-precision micro-machining.

- Advanced Material Processing: Ideal for brittle material cutting, drilling, dicing, and sub-surface marking.

- Compliance: Meets CDRH, ROHS, and CE standards for safety and quality assurance.

- Operational Efficiency: Quick cold start warm-up time of less than 30 minutes and standby warm-up time of less than 20 minutes.

- Environmental Conditions: Operates efficiently within a temperature range of 15 to 30°C and humidity range of 20 to 80% non-condensing.

- Flexible Communication: Equipped with RS-232 communication for easy integration.

- Efficient Cooling: Utilizes water cooling to maintain optimal performance.

Applications

- Injector Drilling

- Medical Device Manufacturing

- Polymer Processing/Machining

- Semiconductor/PV Processing/Wafer Scribing

- High-Precision, High-Speed Micro-machining

- Brittle Material Cutting, Drilling, Dicing & Sub-Surface Marking

Frequently Asked Questions

What is the AOFemto™ Series laser used for?

What is the average power of the AOFemto™ Series laser?

What is the warranty offered by Advanced Optowave Corporation for the AOFemto™ Series laser?

What is the pulse duration of the AOFemto™ Series laser?

What is the beam quality of the AOFemto™ Series laser?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle