Description

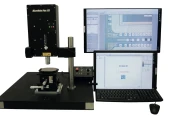

The MicroMake Laser Micromachining System by Bright System is a cutting-edge solution engineered for precise and versatile microprocessing applications. With over 20 years of expertise in laser technology, this compact yet powerful system is designed to meet the demanding requirements of modern manufacturing and research environments.

At its core, the MicroMake system offers exceptional precision, allowing for the ablation and cutting of programmable arbitrary shapes with unmatched accuracy. Its live imaging feature enables real-time monitoring of the machining process, ensuring precise control and optimal results.

Versatility is a hallmark of the MicroMake system, which is capable of working with a wide range of materials, including metals, ceramics, transparent substrates, and polymers. This adaptability is further enhanced by its robust 532/266 nm ns and ps lasers, making it indispensable across industries such as microelectronics, biomedicine, optics, and micromechanics.

Featuring a standard processing area of 1 mm and a spot size as small as 2 µm, the MicroMake system delivers intricate details with utmost precision. Optional features like an XYZ translation stage and different objective lenses offer additional flexibility, catering to a variety of specific requirements.

With its user-friendly design, compact footprint, and low-voltage electrical power requirements, the MicroMake system is ideal for OEM integration and seamless operation in diverse environments. Backed by Bright System's commitment to quality and innovation, the MicroMake Laser Micromachining System sets new standards for precision engineering and microprocessing excellence.

MicroMake 532 Plus: Laser Micromachining System 10kW

Specifications

| Materials: | Metals, Thermoset Plastics, Thermoplastics, Polimers, Ceramics, Glass |

|---|---|

| Laser Type: | DPSS (Nd:YAG) |

| Laser Wavelength: | 532 nm (green) |

| Laser Safety: | Not classified |

| Work Area X: | 150 mm |

| Work Area Y: | 150 mm |

| Processing Speed: | 5 mm/sec |

| Features And Options: | Air-Cooled |

| Lens Magnification: | 10x |

| Working Distance: | 39 mm |

| Spatial Resolution: | 4.5 µm |

| Laser Frequency: | 1 kHz |

| Max Peak Power: | 10 kW |

Features

- Ablation and cutting of programmable arbitrary shapes

- Live imaging of the processed samples during machining

- Suitable for a wide range of materials

- 1 mm standard processing area

- Down to 2 µm spot size

- 532/266 nm ns and ps lasers

- Embedded illumination unit

- Optional XYZ translation stage

Applications

- 3D direct microstructuring

- Precision surface texturing

- Track interruption on PCBs

- Microcoding for anti-counterfeiting

- Thin film removal on hard substrates

- Selective metal removal on ceramic substrates

- Microcorrection on wafers, masks, and displays

- Microdrilling on metals and transparent dielectrics

Frequently Asked Questions

What is the MicroMake Laser Micromachining System?

What are the key features of the MicroMake system?

What applications is the MicroMake system suitable for?

What are the available options for the MicroMake system?

What are the specifications of the MicroMake system?

Is the MicroMake system suitable for OEM integration?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle