Description

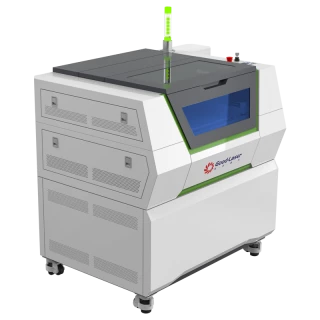

The 1500W fiber laser cutting machine is a highly efficient and precise cutting solution designed for processing thin to medium-thickness metal sheets. Using advanced fiber laser technology, it delivers clean, smooth edges and complex cuts at high speed, making it an ideal tool for industries that require accuracy and productivity. Its 1500W laser source provides stable performance while maintaining lower energy consumption, offering a perfect balance between cost-effectiveness and cutting capability. The 1500W fiber laser cutting machine is the perfect choice for businesses looking for an affordable yet powerful solution to achieve precise and efficient cutting of thin to medium-thickness metal sheets.

1500W Fiber Laser Cutting Machine

Specifications

| Format: | Benchtop |

|---|---|

| Laser Source: | Fiber |

| Laser Output Power: | Not Specified |

| Laser Wavelength: | 1064 nm (IR) |

| Beam Delivery: | Flatbed |

| Work Area X: | 1500 mm |

| Work Area Y: | 3000 mm |

| Work Area Z: | Not Specified |

| Application: | Sheet Cutting |

| Sector: | Professional |

| Materials: | Stainless Steel, Steel/Iron, Steel Alloy, Aluminum, Brass, Copper |

| Voltage Requirement: | 220V - 50Hz |

| Included Options: | CNC, Laser Chiller, High Speed Guide Rail |

| Safety Enclosure: | Not Specified |

| Laser Safety Class: | Class 4 |

| Max Cutting Speed: | Not Specified |

Features

- 1500W Fiber Laser Power: Capable of cutting stainless steel, carbon steel, galvanized sheet, aluminum, brass, and other common metals.

- High Precision Cutting: Produces smooth, burr-free edges with minimal heat distortion.

- Versatile Performance: Suitable for thin to medium plates, typically up to 12–16mm depending on the material.

- Advanced Control System: Supports CAD/CAM software for efficient nesting and complex pattern cutting.

- Low Operating Costs: Reduced maintenance and no need for costly consumables compared to traditional cutting methods.

Applications

- Metal Fabrication: Cutting parts, panels, and custom designs with precision.

- Automotive Industry: Processing sheet metal components and structural parts.

- Electronics & Appliances: Precision cutting of casings, brackets, and housings.

- Construction & Architecture: Decorative panels, metal doors, windows, and structural elements.

- Furniture Manufacturing: Metal frames, supports, and artistic designs.

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle