Description

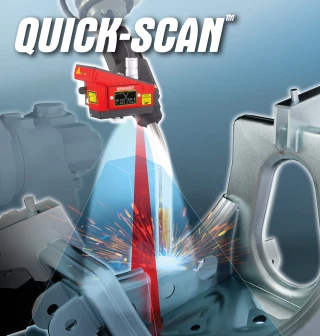

Introducing the High-Speed Compact 3D Laser-Vision System, a groundbreaking innovation designed to revolutionize high-power laser robotic applications. This advanced system, known as the LAS-TRAC /E, integrates a super powerful embedded processor, ensuring unparalleled performance and precision in demanding industrial environments. Its compact design does not compromise on power, making it an ideal choice for facilities looking to enhance their laser processing capabilities without the need for additional controllers.

The LAS-TRAC /E is engineered to excel in a variety of tasks, including seam tracking, seam finding, and adaptive welding. Its user-friendly interface ensures that operators can easily navigate and utilize the system to its full potential, minimizing downtime and maximizing productivity. The inclusion of an alphanumeric OLED display provides clear and concise information, allowing for real-time monitoring and adjustments as needed.

This system is not only about performance but also about efficiency and ease of use. By eliminating the need for additional controllers, the LAS-TRAC /E streamlines operations, reducing complexity and potential points of failure. Whether you are involved in seam finding, inspection, or tracking, this laser-vision system offers a robust solution that adapts to your specific needs, ensuring consistent and reliable results.

LAS-TRAC/E™ High-Speed Seam Tracking Laser-Vision System

Specifications

| Working Distance: | 6.5 – 16 mm |

|---|---|

| Max Temperature: | 50 degC |

| System Type: | Seam tracking laser-vision system |

| Welding Applications: | Laser welding, laser hybrid welding, laser brazing |

| Tracking Method: | Real-time laser seam tracking |

Features

- Real-Time Seam Tracking: Ensures accurate positioning of the laser weld spot within the joint.

- High-Speed Performance: Delivers rapid scanning for fast-paced production environments.

- Adaptive Welding Control: Adjusts voltage, wire feed, and travel speed for optimal weld bead formation.

- Handles Complex Trajectories: Capable of tracking curved joints and variable seam paths.

- Multi-Material Compatibility: Works with carbon steel, stainless steel, and reflective aluminum alloys.

- Robust and Compact Design: Engineered for industrial durability and seamless integration into robotic systems.

Applications

- Robotic Laser Welding: Ensures precision seam tracking for consistent welds.

- Laser Hybrid Welding: Provides adaptability for complex material combinations.

- Laser Brazing: Enables accurate brazing of linear and curved joints.

- Automotive Manufacturing: Ideal for body-in-white, roof-to-body, and trunk lid joining.

- Aerospace & Industrial Fabrication: Reliable tracking for safety-critical and complex components.

Frequently Asked Questions

What is the HIGH-SPEED COMPACT 3D LASER-VISION SYSTEM used for?

Does the system require an additional controller?

What kind of display does the system have?

Is the system user-friendly?

What are the key features of the LAS-TRAC /E system?

What type of processor is embedded in the system?

How can I get more information about the system?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle