Description

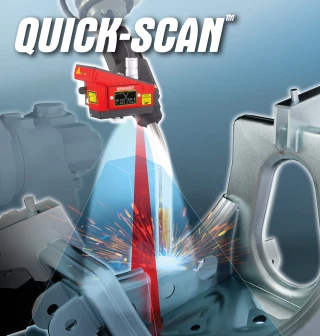

The Measurement System for Arc Welded Components, known as ARC-SCANTM, is a cutting-edge solution designed to revolutionize the welding industry. This advanced system provides real-time quality control for welding processes, ensuring that every component meets the highest standards of precision and reliability. By integrating seamlessly into existing workflows, ARC-SCANTM enhances the efficiency and accuracy of welding operations, making it an indispensable tool for manufacturers seeking to optimize their production lines.

One of the standout features of ARC-SCANTM is its ability to perform high-speed inspections with a high scanning frame rate. This capability allows for rapid detection and measurement of defects, ensuring that any issues are identified and addressed promptly. The system's exceptional accessibility to the weld site further enhances its effectiveness, allowing operators to monitor and improve welding processes with ease. This accessibility is complemented by global process monitoring capabilities, which provide a comprehensive overview of welding operations and facilitate continuous improvement.

ARC-SCANTM is designed with the future in mind, featuring IIoT readiness that enables seamless integration with modern industrial systems. Its compact design and long stand-off distance make it suitable for a wide range of applications, while its accessible database supports traceability and process improvement efforts. By leveraging the power of ARC-SCANTM, manufacturers can achieve significant improvements in welding robot efficiency, ultimately leading to enhanced productivity and product quality.

ARC-SCAN: Real-time Welding Quality Control System

Specifications

| Working Distance: | 100 – 250 mm |

|---|---|

| Max Temperature: | 50 degC |

| Defect Detection Accuracy: | High precision measurement and detection |

| Scanning Frame Rate: | High-speed, real-time scanning |

Features

- Real-time Welding Quality Control: Monitor welding processes in real-time to ensure high-quality outcomes.

- High Scanning Frame Rate and Fast Inspection Speed: Quickly scan and inspect components to maintain efficiency.

- Accurate Defect Detection and Measurement: Precisely identify and measure defects for improved quality assurance.

- Good Accessibility to the Weld: Easily access welds for thorough inspection and maintenance.

- Global Process Monitoring Capabilities: Monitor welding processes globally for consistent quality control.

- Continuous Improvement of Welding Robot Efficiency: Enhance the efficiency of welding robots through ongoing improvements.

- Accessible Database for Traceability and Process Improvement: Utilize a comprehensive database for tracking and enhancing processes.

- Long Stand-off: Maintain a safe and effective distance during inspections.

- Extremely Compact: Benefit from a compact design that fits into various environments.

- IIoT Ready: Integrate seamlessly with Industrial Internet of Things (IIoT) systems for advanced connectivity.

Applications

- Automotive Manufacturing: Ensures reliable weld quality in high-volume vehicle production.

- Aerospace Industry: Provides precise defect detection for safety-critical components.

- Heavy Equipment Fabrication: Monitors structural welds for durability and compliance.

- Robotic Welding Systems: Enhances efficiency by continuously measuring weld performance.

- Industrial Quality Assurance: Supports inspection, traceability, and process validation.

Frequently Asked Questions

What is ARC-SCAN?

How does ARC-SCAN ensure welding quality?

What are the key features of ARC-SCAN?

Is ARC-SCAN suitable for industrial environments?

Can ARC-SCAN help with process improvement?

What does 'IIoT Ready' mean for ARC-SCAN?

How can I get more information about ARC-SCAN?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle