Description

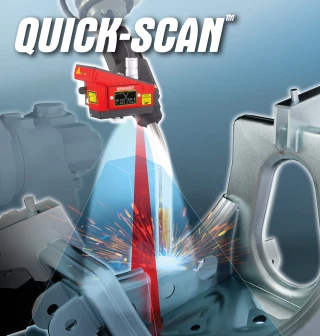

AUTO-TRAC / PLC is a state-of-the-art 3D laser-vision system meticulously engineered for joint tracking and adaptive process control, specifically tailored for special purpose welding machines. This innovative system is designed to enhance the precision and efficiency of welding operations, ensuring optimal results with minimal manual intervention. Its advanced technology allows for seamless integration into existing workflows, providing a robust solution for industries seeking to improve their welding processes.

One of the standout features of the AUTO-TRAC / PLC is its user-friendly interface, which makes it accessible to operators of all skill levels. The system's intuitive design ensures that users can quickly learn and operate the system, reducing downtime and increasing productivity. This ease of use does not compromise its reliability; the AUTO-TRAC / PLC is built to withstand the demanding conditions of industrial environments, delivering consistent performance over time.

In addition to its operational benefits, the AUTO-TRAC / PLC offers a cost-efficient solution for businesses looking to optimize their welding processes. By automating joint tracking and process control, the system reduces the need for manual oversight, leading to significant savings in labor costs. Furthermore, its precision and adaptability help minimize material waste, contributing to overall cost reductions. The AUTO-TRAC / PLC represents a smart investment for companies aiming to enhance their welding capabilities while maintaining budgetary constraints.

AUTO-TRAC PLC 3D Laser-Vision System for Welding Machines

Specifications

| Working Distance: | 28 – 105 mm |

|---|---|

| Max Temperature: | 50 degC |

Features

- Easy-to-Use: Simplifies operation with user-friendly controls, ensuring quick setup and minimal training.

- Reliable: Built for consistent performance, reducing downtime and maintenance needs.

- Cost-Efficient: Offers a high return on investment by optimizing welding processes and reducing waste.

- Complete 3D Laser-Vision System: Provides precise joint tracking and adaptive process control for enhanced welding accuracy.

- Designed for Special Purpose Welding Machines: Tailored to meet the unique demands of specialized welding applications.

Applications

- Easy-to-Use: Simplifies operation for users of all skill levels.

- Reliable: Ensures consistent performance and minimal downtime.

- Cost-Efficient: Offers a budget-friendly solution without compromising quality.

- Complete 3D Laser-Vision System: Provides advanced joint tracking and adaptive process control.

- Designed for Special Purpose Welding Machines: Tailored for specialized welding applications.

Frequently Asked Questions

What is the AUTO-TRAC / PLC TM system?

What are the key features of the AUTO-TRAC / PLC TM?

What is the primary application of the AUTO-TRAC / PLC TM?

How does the AUTO-TRAC / PLC TM improve welding processes?

Is the AUTO-TRAC / PLC TM system cost-efficient?

Can I request more information about the AUTO-TRAC / PLC TM?

What makes the AUTO-TRAC / PLC TM reliable?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle