Description

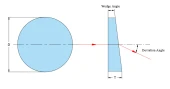

Wedge Prisms are typically used to deflect the incident light beam at a certain deflection angle to a specified direction. When used in pairs, by the relative rotation of the two wedge prisms, the outgoing light beam can be positioned in any direction within an angular cone centered on the incident light beam. The wedge angle of the wedge prism and the anti-reflection coating on the back surface can reduce the ghost interference reflected from the rear surface. High-precision substrates ensure the accuracy of the wavefront of the reflected and transmitted light.UM Optics can provide wedge prisms in a variety of materials and sizes.

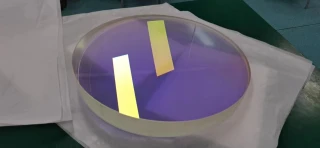

Custom High Precision Optical Wedge Prisms

Specifications

| Diameter: | 30 mm |

|---|---|

| Thickness (T): | 3 mm |

| Wedge Angle: | 4 deg |

| Material: | BK7 |

| Dimension Tolerance: | +0/-0.1mm |

| Surface Quality: | 60-40 |

| Surface Accuracy: | λ/4 |

| Angle Tolerance: | ±30'' |

Features

- Multi-Material Customization: Available in diverse optical materials (CaF₂, BaF₂, BK7, K9, fused silica, silicon, etc.) to match different spectral requirements (UV to MIR) and application scenarios.

- Precision Beam Deflection: Tight angular tolerance (±3–±30 arcsec) and surface flatness ≤λ/4 @632.8 nm ensure accurate, repeatable beam deviation without significant displacement, critical for high-precision optical alignment.

- Broad Spectral Adaptability: Depending on the selected material, the prisms exhibit excellent transmittance across UV (down to 0.13 μm for CaF₂), visible, NIR, and MIR (up to 15 μm for silicon) ranges; AR coatings further optimize light throughput (>99%).

- Stable Mechanical Performance: High scratch resistance and chemical inertness (varies by material) ensure long-term reliability in industrial, laboratory, and harsh environments (e.g., high humidity, temperature fluctuations).

- Flexible Custom Solutions: Support custom wedge angles (including ultra-small angles <0.5°), shapes (round, square, rectangular), edge radii, coatings, and material grades (laser-grade, imaging-grade) to meet specific application needs.

Applications

- Optical Alignment & Calibration: Used in laser systems, optical spectrometers, and imaging equipment to correct beam deviation and adjust optical paths

- Laser Processing: Core components in laser cutting, welding, and marking machines for beam steering and angle fine-tuning, suitable for high-power laser systems

- Medical Devices: Integrated into diagnostic imaging equipment (e.g., endoscopes), laser therapy tools, and ophthalmic devices, leveraging high precision and stable optical performance

- Industrial Inspection: Employed in machine vision systems, optical sensors, and non-destructive testing (NDT) equipment for precise light path adjustment

- Scientific Research: Used in optical experiments, spectroscopy, and astronomy equipment, ideal for high-precision research requiring low dispersion and stable performance

- Consumer Electronics: Applied in high-end camera lenses, projectors, and optical sensors for consumer devices that require precise optical performance

Frequently Asked Questions

What are the key advantages of your wedge prisms for high-precision optical systems?

Our wedge prisms stand out with low optical dispersion, high thermal stability, and excellent resistance to high-power laser irradiation. These properties ensure consistent optical performance even in variable temperature environments, making them ideal for high-precision applications such as scientific research, high-power laser systems, and advanced imaging equipment.

What are the key differences in optical performance between round and square/rectangular wedge prisms?

Round wedge prisms are ideal for circular beam systems, minimizing beam clipping and simplifying alignment with cylindrical optical mounts. Square/rectangular prisms, by contrast, suit rectangular beam paths (e.g., machine vision) and enable tighter packing in multi-prism assemblies. Optically, both maintain the same beam deviation accuracy—performance differences depend on size/tolerance, not shape.

For the UV to Far IR wavelength range, do different substrates (Fused Silica vs. N-BK7) affect performance at specific wavelengths?

Yes. Fused Silica offers superior transmittance in UV (down to 180nm) and NIR/Far IR (up to 2500nm), while N-BK7 is optimized for visible-NIR (400nm–2000nm). Zerodur, by contrast, has ultra-low thermal expansion—ideal for wavelength-stable systems (e.g., astronomy) across all bands.

Can this wedge prism be coated, and what coatings are compatible with its substrate options?

Yes. We offer anti-reflective (AR) coatings optimized for your target wavelength: e.g., UV AR for Fused Silica (180nm–400nm), visible AR for N-BK7 (400nm–700nm), and broadband AR for Far IR.

Similar Products

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle