Description

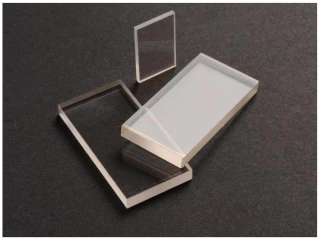

Experience unparalleled precision with our Thin Film Polarizers, expertly crafted to separate s- and p-polarization components. These polarizers are specifically designed for high energy laser applications, offering a superior alternative to traditional Glan Laser Polarizers or Polarizing Beamsplitter Cubes. With a high damage threshold, these polarizers ensure durability and reliability in demanding environments.

At LASERSTEC, we utilize super polished substrates and advanced Ion Beam Sputtering (IBS) coating technology to deliver Thin Film Polarizers with exceptional performance. Our polarizers boast a high extinction ratio, catering to a wide wavelength range from UV to NIR. The precision polishing technology ensures a customized polarizer with an extinction ratio of up to 10000:1 and a transmission percentage (Tp) greater than 98% at continuous wave (CW) with a 120x60mm aperture.

Our Thin Film Polarizers are meticulously engineered to meet the highest standards of quality and performance. The use of premium materials such as BK7 or Fused Silica, combined with a surface flatness of λ/10 at 632.8nm and a surface quality of 10/5 S/D as per MIL-PRF-13830B, ensures optimal functionality. With a wedge of less than 30 arc seconds and an angle of incidence at Brewster angle ±2° or 45° ±2°, these polarizers are built to handle damage thresholds exceeding 10J/cm² for 10ns pulses at 1064nm.

Choose from a variety of dimensions and materials to suit your specific needs, with options available for different wavelengths including 1064nm, 1053nm, 532nm, 808nm, 755nm, and 1550nm. Whether you require a compact size or a larger aperture, our Thin Film Polarizers are designed to deliver exceptional performance and reliability in any high energy laser application.

Thin Film Polarizer | High Damage Threshold

Specifications

| Substrate Material: | UVFS |

|---|---|

| Polarizing Material: | Custom |

| Shape: | Custom |

| Size: | 300 mm |

| Wavelength Range: | 355 – 2200 nm |

| Max Extinction Ratio: | >= 1000:1 |

| Surface Flatness: | <= Lambda/10 |

| Surface Quality (Scratch-Dig): | 20-10 |

Features

- High Energy Laser Applications: Thin Film Polarizers are specifically designed for high energy laser applications, offering a reliable alternative to Glan Laser Polarizers or Polarizing Beamsplitter Cubes.

- Superior Damage Threshold: With a damage threshold of over 10J/cm² for 10ns pulses at 1064nm, these polarizers are built to withstand intense laser environments.

- High Extinction Ratio: Achieve an extinction ratio ranging from 200:1 to 10000:1, ensuring superior separation of s- and p-polarization components.

- Wide Wavelength Range: Suitable for wavelengths from UV to NIR, including common laser wavelengths such as 1064nm, 1053nm, 532nm, 808nm, 755nm, and 1550nm.

- Precision Polishing and Coating: Utilizing super polished substrates and Ion Beam Sputtering (IBS) coating technology for high-quality performance.

- Customizable Options: Available in various dimensions and materials, including BK7 and Fused Silica, to meet specific application requirements.

- Surface Quality and Flatness: Features a surface quality of 10/5 S/D as per MIL-PRF-13830B and a surface flatness of λ/10 @632.8nm.

- Angle of Incidence: Designed for Brewster angle ±2° or 45° ±2°, optimizing performance for specific laser setups.

- Large Aperture: Offers a large aperture size of up to 120x60mm, accommodating various laser beam sizes.

Applications

- High Energy Laser Applications: Thin Film Polarizers are ideal for high energy laser systems due to their high damage threshold.

- Polarization Separation: These polarizers effectively separate s- and p-polarization components.

- Alternative to Traditional Polarizers: They serve as an alternative to Glan Laser Polarizers or Polarizing Beamsplitter Cubes.

- Customizable Extinction Ratio: Offers high extinction ratios up to 10000:1 with Tp>98%@CW.

- Wide Wavelength Range: Suitable for wavelengths from UV to NIR.

- Precision and Quality: Manufactured using super polished substrates and Ion Beam Sputtering deposition technology for high precision and quality.

- Various Material Options: Available in BK7 or Fused Silica materials.

- Multiple Dimensions: Available in various dimensions to suit different application needs.

- High Surface Quality: Features a surface quality of 10/5 S/D as per MIL-PRF-13830B standards.

- High Damage Threshold: Can withstand >10J/cm², 10ns pulse@1064nm.

Frequently Asked Questions

What is a Thin Film Polarizer?

What materials are used to make Thin Film Polarizers?

What is the extinction ratio of Thin Film Polarizers?

What is the damage threshold of these polarizers?

What are the typical wavelengths supported by Thin Film Polarizers?

What is the surface quality of Thin Film Polarizers?

What is the angle of incidence for Thin Film Polarizers?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle