Description

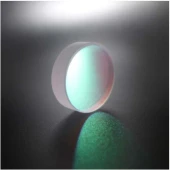

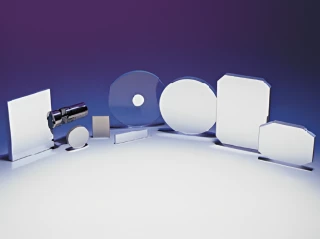

High precision optical mirrors made of BK7 material, available at various sizes

Round high precision BK7 mirrors are available in diameters ranging from Φ10.0 mm to Φ76.2 mm, while square mirrors come in sizes from 5.0×5.0 mm to 50.0×50.0 mm. Thickness options range from 0.5 mm to 50.0 mm, allowing for customization based on specific application requirements. This extensive range of sizes and specifications ensures that customers can find the perfect mirror for their needs.

These high precision optical mirrors made of BK7 material are available in a range of specifications to suit different precision requirements. They are made from high-quality BK7 (CDGM H-K9L) material, ensuring durability and reliability. The company offers both general and high-precision mirrors, with varying tolerances in dimension and thickness to meet specific customer needs. Surface quality, clear aperture, flatness, and parallelism are meticulously controlled to ensure optimal performance. Additionally, these high precision mirrors can be coated with HR, aluminum, or silver coatings to enhance their reflective properties.

BK7 mirrors from Shandong Yanggu Constant Crystal Optics are integral to scientific apparatus such as telescopes and lasers, as well as cameras and industrial machinery. While most mirrors are designed for visible light, the company also offers mirrors tailored for other types of waves or electromagnetic radiation wavelengths, catering to non-optical instruments. This versatility ensures that the mirrors meet the diverse needs of various industries and applications.

Shandong Yanggu Constant Crystal Optics, Inc. has been a leader in the manufacturing of optical glass components since 2006. With a commitment to precision and quality, the company specializes in producing high-performance mirrors designed for a variety of applications. These mirrors are crafted with surfaces that exhibit high reflection, making them ideal for forming clear and accurate images. The most common type of mirror produced is the plane mirror, which features a flat surface. However, the company also manufactures curved mirrors that can magnify, diminish, or focus light, and even distort reflected images for specialized uses.

High Precision Optical Mirrors, BK7 Material, Various Sizes

Specifications

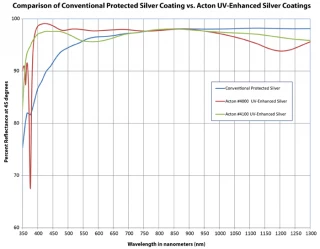

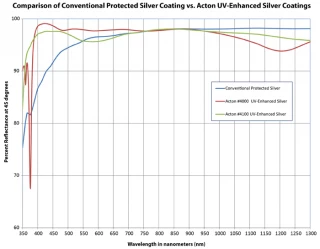

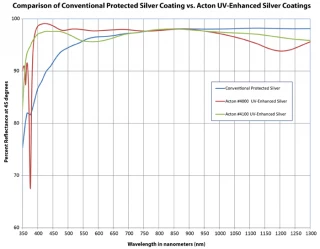

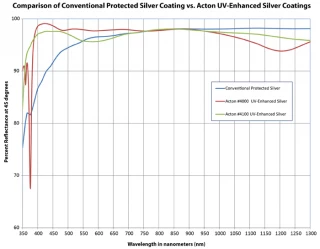

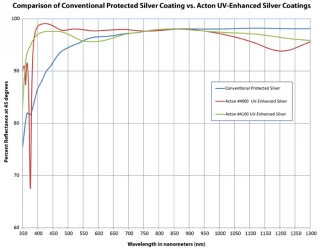

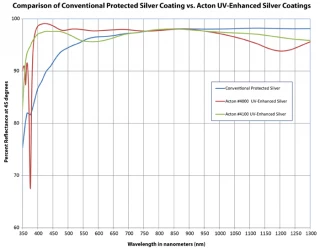

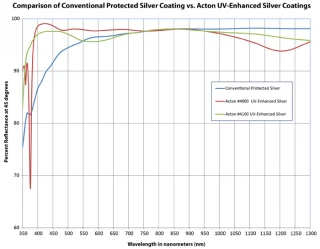

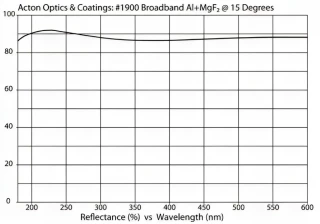

| Reflective Coating: | UV-Enhanced Aluminum, Protected Silver, Custom, Protected Aluminum |

|---|---|

| Substrate: | BK7 |

| Average Reflectance: | 90 % |

| Wavelength Range: | 400 – 1100 nm |

| Surface Flatness: | 1 lambda, lambda/10 |

| Surface Quality: | 10-5 scratch-dig, 60-40 scratch-dig |

| Diameter: | 10 mm |

| Thickness: | 2 mm |

| Shape: | Round, Square, Rectangle |

| Clear Aperture (High Precision): | >95% |

| Thickness Options: | 0.5, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 50.0 mm |

| Square Shape Sizes: | 5.0×5.0, 10.0×10.0, 15.0×15.0, 20.0×20.0, 25.0×25.0, 50.0×50.0 mm |

| Round Shape Diameters: | Φ10.0, Φ12.7, Φ15.0, Φ20.0, Φ25.4, Φ38.1, Φ50.8, Φ76.2 mm |

| Coating: | HR coating, Al coating, Ag coating |

| Parallelism (High Precision): | <3 arcsec |

| Parallelism (General): | <3 arcmin |

| Flatness (High Precision): | λ/10 |

| Flatness (General): | 1λ |

| Material: | BK7 (CDGM H-K9L) |

| Clear Aperture (General): | >80% |

| Surface Quality (High Precision): | 10/5 |

| Surface Quality (General): | 60/40 |

| Thickness Tolerance (High Precision): | ±0.005mm |

| Thickness Tolerance (General): | ±0.2mm |

| Dimension Tolerance (High Precision): | +0.0/-0.02mm |

| Dimension Tolerance (General): | +0.0/-0.2mm |

Features

- Experience: Specializing in optical glass components manufacturing since 2006.

- Product: High-quality mirrors made of BK7 material suitable for various applications.

- Surface: High reflection, smooth enough to form an image.

Applications

- Scientific Apparatus: High precision mirrors are essential components in scientific instruments such as telescopes and lasers, where they help in focusing light and forming images.

- Cameras: Used in cameras to direct light and create images, these high precision BK7 mirrors are crucial in the design of various optical systems.

- Industrial Machinery: Our high precision mirrors are used in industrial settings for applications such as laser cutting and precision measurement tools.

- Non-Optical Instruments: Mirrors designed for non-visible wavelengths are used in instruments that operate outside the visible spectrum, such as infrared or ultraviolet devices.

Frequently Asked Questions

What types of mirrors does SHANDONG YANGGU CONSTANT CRYSTAL OPTICS, INC. manufacture?

What materials are used in the manufacturing of these high precision mirrors?

What are the dimension tolerances for the mirrors?

What surface quality can be expected from these mirrors?

What are the clear aperture specifications for these mirrors?

What coatings are available for these mirrors?

What are the typical sizes available for these optical mirrors?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle