Description

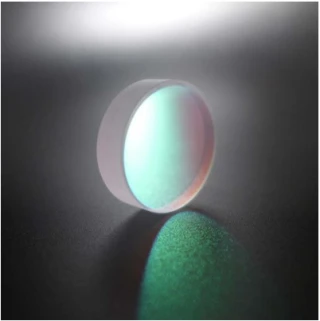

Silicon gold-coated mirrors consist of a high-quality silicon substrate coated with a gold reflective layer,and is commonly used in various optical systems, such as telescopes, microscopes, lasers, etc.The main advantages of gold-plated mirrors are high reflectivity, good stability, and strong corrosion resistance, and can work stably for a long time under harsh environmental conditions. In addition, it can adjust reflectivity and spectral characteristics through different coating processes to meet different application needs.

The manufacturing process of mirrors usually involves coating an optical silicon substrate with a metallic gold film, followed by fine polishing and coating to ensure high reflectivity and smooth surface quality. Since metallic gold has high reflectivity and excellent conductive properties, gold-plated reflectors can effectively reflect light and maintain the stability and consistency of light.

Custom Gold Coating Silicon Reflective Optical Mirror

Specifications

| Reflective Coating: | Protected Gold |

|---|---|

| Substrate: | Si |

| Average Reflectance: | 90 % |

| Wavelength Range: | 800 – 2000 nm |

| Surface Flatness: | lambda/4 |

| Surface Quality: | 60-40 scratch-dig |

| Diameter: | 30 mm |

| Thickness: | 2 mm |

| Shape: | Round |

Features

- Wide Spectral Performance:Suitable for applications from near-infrared to far-infrared, making it ideal for broadband IR optical systems、

- Excellent Thermal Stability:Silicon substrate offers high thermal conductivity and low thermal deformation, ensuring stable optical performance under high-power or elevated-temperature conditions

- Durable Metallic Coating:Gold coatings exhibit strong chemical stability and oxidation resistance in typical infrared operating environment

- Low Absorption in Infrared:Minimizes thermal loading and optical losses in high-power infrared systems

- Customizable Specifications:Available in various diameters, thicknesses, shapes (round, rectangular), and surface quanlity

Applications

- Infrared Laser Systems:Suitable for CO₂ lasers and other infrared laser systems as beam delivery and reflective components

- FTIR and Infrared Spectroscopy:Applied in Fourier-transform infrared (FTIR) spectrometers and analytical instruments

- Aerospace and Defense Systems:Used in infrared sensing, tracking, and detection systems operating in harsh or high-temperature environments

- Industrial and Scientific Instrumentation:Deployed in industrial inspection equipment, research optics, and laboratory infrared setups

Frequently Asked Questions

Why use a gold coating for infrared mirrors?

What advantages does a silicon substrate provide?

Which wavelength ranges are best suited for silicon gold-coated mirrors?

Are silicon gold-coated mirrors suitable for high-power laser applications?

How do silicon gold-coated mirrors compare to dielectric mirrors?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle