Description

Our thin film coatings offer precision and reliability, tailored to meet the unique demands of optical applications. Among these coatings, our plate beamsplitters stand out as essential components for manipulating light paths in various optical systems. These beamsplitters are expertly designed to split a beam of light into separate paths, providing flexibility in the percentages of transmission and reflection, as well as the wavelength region, to suit specific applications.

The first surface of our plate beamsplitters features an all dielectric coating, ensuring optimal performance and durability. To further enhance functionality, the second surface is typically antireflection coated, which significantly reduces secondary reflections and ghosting. We offer customization options to optimize the coating according to your specifications, including the reflection/transmission (R/T) ratio, angle of incidence, and wavelength.

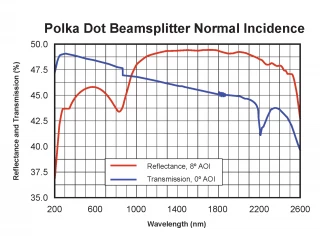

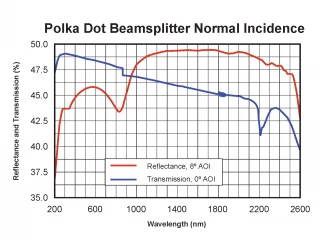

For example, we recently fulfilled a requirement for a plate beamsplitter with a 25% reflection and 75% transmission ratio at an average polarization of 550nm on float glass at a 45° angle. Additionally, another customer specification called for a 50/50 ±5% split at 1.06µm, with greater than 20% reflection in the visible spectrum at a 45° angle on BK-7 glass. These examples illustrate our capability to deliver precise and customized solutions for diverse optical needs.

Custom Plate Beamsplitters

Specifications

| Largest Dimension: | 600 mm |

|---|---|

| Thickness: | 2 mm |

| Substrate: | BK7, Fused Silica, Float Glass, Custom |

| Wavelength Range: | 250 – 2500 nm |

Features

- Customizable Transmission and Reflection: Our plate beamsplitters are designed to split a beam of light into separate paths, with customizable percentages of transmission and reflection to suit your specific application needs.

- All Dielectric Coating: The first surface features an all dielectric coating, ensuring high performance and durability.

- Antireflection Coated Second Surface: The second surface is generally antireflection coated to minimize secondary reflections and ghosting, enhancing the clarity and quality of the split beam.

- Optimized Coating: We can optimize the coating to meet your specifications, including R/T ratio, angle of incidence, and wavelength.

- Specific Requirements: Capable of achieving a 25% reflection and 75% transmission at 550nm on float at a 45° angle for average polarization.

- Versatile Performance: Can achieve a 50/50 ±5% split at 1.06µm and greater than 20% reflection in the visible spectrum at 45° for average polarization on BK-7 substrates.

Applications

- Optical Instrumentation: Thin film coatings are essential in optical instruments where precise control over light transmission and reflection is required.

- Laser Systems: Beamsplitters are used in laser systems to direct beams into different paths for various processing or measurement tasks.

- Scientific Research: In laboratories, beamsplitters are crucial for experiments that involve splitting light beams for analysis or measurement.

- Photography and Imaging: Coatings help improve image quality by reducing unwanted reflections and enhancing light transmission in cameras and imaging devices.

- Telecommunications: Optical coatings are used in fiber optics and other communication devices to manage light signals efficiently.

- Medical Devices: In medical imaging and diagnostic equipment, precise light management is critical for accurate results, making thin film coatings essential.

- Astronomy: Telescopes and other astronomical instruments use beamsplitters and coatings to observe celestial objects with high clarity.

- Industrial Applications: Beamsplitters are used in various industrial applications, including material processing and quality control systems.

- Consumer Electronics: Devices such as projectors and display screens use thin film coatings to enhance image clarity and brightness.

- Military and Defense: Optical coatings are used in targeting systems, surveillance, and other defense technologies for improved performance.

Frequently Asked Questions

What is a plate beamsplitter?

What are the applications of plate beamsplitters?

What are the coatings used in plate beamsplitters?

Can the coating of plate beamsplitters be optimized?

What was the requirement for a specific plate beamsplitter?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle