Description

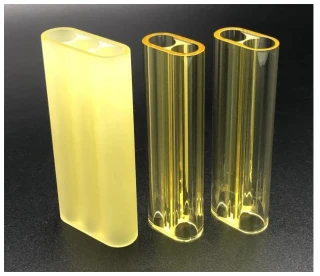

MACOR® Machinable Glass Ceramic is a revolutionary material that combines the beneficial properties of ceramics with the convenience of easy fabrication. This unique material allows for precision machining using standard machine tools, eliminating the need for specialized equipment or expertise in ceramics. As a result, MACOR® opens up a world of possibilities for industries requiring high-performance ceramic components without the traditional complexities and costs associated with ceramic manufacturing.

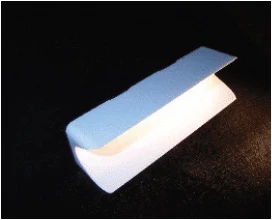

The production of MACOR® involves melting and casting using conventional glass-making techniques. This fluorine-rich glass undergoes a controlled heat treatment process, resulting in the formation of fluorphlogopite mica crystals within an alumino-borosilicate glass matrix. The intricate structure, characterized by a 55% crystalline phase with uniformly distributed mica crystals, imparts MACOR® with its distinctive properties. This material resembles opal glass in appearance, adding an aesthetic dimension to its functional benefits.

MACOR® is renowned for its exceptional physical properties. It can withstand continuous use at temperatures up to 800°C, making it suitable for high-temperature applications. Its thermal expansion coefficient aligns well with most metals and sealing glasses, ensuring compatibility in various assemblies. Moreover, MACOR® is non-flammable, non-wetting, and exhibits zero porosity, maintaining structural integrity even under demanding conditions. As an excellent electrical and thermal insulator, it is ideal for applications requiring reliable insulation at high voltages and temperatures.

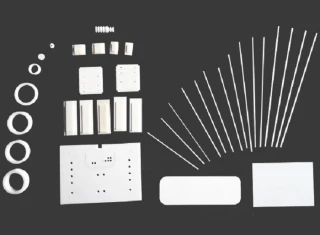

One of the standout features of MACOR® is its machinability. It allows for tight machining tolerances up to 10 microns and can achieve a surface finish of less than 0.5 micron. The material can be polished to an extraordinary smoothness, ensuring precision in critical applications. Conventional machining processes are applicable, and the only limitation is the equipment and expertise of the machinist. This versatility makes MACOR® a preferred choice for custom and complex component manufacturing.

In addition to its machinability, MACOR® offers versatile options for sealing, joining, and metallizing. It can be joined to itself or other materials through various methods, including soldering of metallized parts, brazing, and epoxy bonding. These techniques ensure strong joints and vacuum-tight seals, expanding its utility across different applications. Whether through mechanical joints or advanced metallization processes, MACOR® provides reliable solutions for intricate assemblies.

MACOR Machinable Glass Ceramic

Specifications

| Material: | Ceramic |

|---|---|

| Type Of Ceramic: | Not Applicable |

| Component Type: | Other |

| Continuous Use Temperature: | 800°C |

| Volume Percent Crystalline Phase: | 55% |

| Mean Crystal Size: | 20 microns |

| Machining Tolerances: | 10 microns (.0005”) |

| Surface Finish: | less than 0.5 micron (20 microinch) |

| Polished Smoothness: | 125 angstroms (0.5 microinch) average roughness |

Features

- High Use Temperature: MACOR® machinable glass ceramic can withstand continuous use up to 800°C, making it ideal for high-temperature applications.

- Non-Flammable: This material is non-flammable, ensuring safety in a variety of environments.

- Excellent Electrical and Thermal Insulator: MACOR® provides superior insulation properties, making it suitable for electrical and thermal applications.

- Dimensionally Stable: The material maintains its shape and size under various conditions, ensuring reliability and precision.

- Easy Machinability: MACOR® can be fabricated using ordinary machine tools, eliminating the need for specialized equipment and reducing production costs.

- Zero Porosity and Non-Wetting: This glass ceramic exhibits zero porosity and is non-wetting, enhancing its performance in critical applications.

- Tight Machining Tolerances: Achieve machining tolerances up to 10 microns (.0005”) and a surface finish of less than 0.5 micron (20 microinch).

- Versatile Joining and Sealing Options: MACOR® can be joined or sealed using various methods, including soldering, brazing, epoxy, and sealing glass, offering flexibility in design and assembly.

- Vacuum Compatibility: When properly baked out, MACOR® will not outgas in vacuum environments, making it suitable for aerospace and scientific applications.

Applications

- Scientific Instrumentation: Ideal for high-precision electrical and thermal insulating parts.

- Aerospace Components: Suitable for lightweight, machinable, and heat-resistant structures.

- Vacuum Systems: Non-outgassing ceramic for vacuum-tight applications.

- Prototype Fabrication: Enables rapid and precise ceramic prototype development.

- High-Temperature Insulation: Provides thermal and electrical insulation in furnaces and heaters.

Frequently Asked Questions

What is MACOR® machinable glass ceramic?

What are the benefits of using MACOR® machinable glass ceramic?

How is MACOR® machinable glass ceramic manufactured?

What are the machining tolerances for MACOR® machinable glass ceramic?

How can MACOR® machinable glass ceramic be joined or sealed to other materials?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle