Description

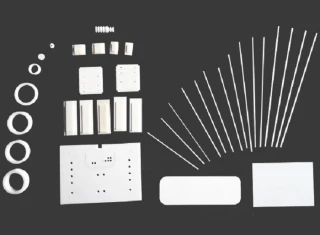

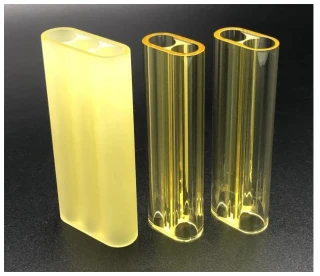

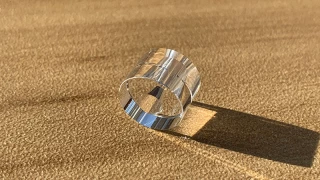

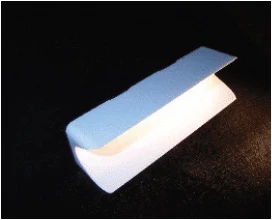

The Accuflect® IR reflector is a cutting-edge solution designed for solar cell thermal processing. This innovative product excels as a medium wave and short wave infrared reflector, delivering outstanding performance that extends well into the visible wavelengths. Its highly efficient diffuse reflection characteristics make it an indispensable component in the realm of solar cell manufacturing, catering to both crystalline and thin film segments of the industry.

In the intricate world of solar cell production, the Accuflect® IR reflector plays a pivotal role. It enables a range of processes that are crucial for the efficient manufacturing of solar cells. By utilizing short wave emitters with emission wavelengths ranging from 1 to 2 microns, this reflector allows for exceptionally high watt densities. Furthermore, the peak emission wavelength can be precisely "tuned" to align with the absorption spectrum of various solar cell materials, ensuring optimal energy transfer and process efficiency.

The advantages of integrating Accuflect® IR into solar cell fabrication processes are manifold. It provides more uniform infrared radiation within the heat process zone, allowing solar materials to perceive a planar emission source rather than a line or point source, thereby reducing process variability. Additionally, the refractoriness of the material eliminates the need for active cooling of the reflector surfaces, while its low thermal impedance facilitates tight process control loops. The cleanliness of high-temperature process zones is maintained, and the recuperative effect of reflection back onto the emitters significantly reduces electrical power input. Moreover, radiation emitted from the warm reflector surfaces aids in heating the solar materials, further enhancing process efficiency.

Accuflect IR Solar Cell Furnace Reflector

Specifications

| Material: | Ceramic |

|---|---|

| Type Of Ceramic: | Not Applicable |

| Component Type: | Reflectors |

| Emission Wavelength: | 1 to 2 microns |

Features

- High-Efficiency Infrared Reflection: Accuflect® IR provides excellent medium and short wave infrared reflection, extending performance into visible wavelengths, making it ideal for solar cell manufacturing.

- Versatile Applications: Suitable for various processes in both crystalline and thin film solar cell manufacturing, including preheating, drying, firing of metallized layers, deposition of antireflection coatings, rapid thermal annealing, and cell-to-cell bonding.

- Optimized Infrared Systems: Utilizes short wave emitters with emission wavelengths of 1 to 2 microns, allowing for high watt densities and tunable peak emission wavelengths to match solar cell material absorption spectra.

- Uniform Heat Distribution: Provides more uniform infrared radiation in the heat process zone, with solar materials perceiving a planar emission source, reducing process variability.

- Refractory Design: Eliminates the need for active cooling of reflector surfaces, enhancing process efficiency and control.

- Low Thermal Impedance: Enables tight process control loops, ensuring consistent quality and performance.

- Clean and Efficient: Maintains cleanliness in high-temperature zones and leverages the recuperative effect of reflection to reduce electrical power input.

- Enhanced Process Efficiency: Radiation from warm reflector surfaces contributes to heating solar materials, improving overall process efficiency.

Applications

- Solar Cell Preheating: Efficient preheating prior to sputtering or diffusion processes.

- Drying and Firing: Supports drying stages and metallized layer firing for solar cells.

- Anti-Reflection Coating Deposition: Enhances deposition uniformity and efficiency.

- Rapid Thermal Annealing: Enables precise annealing of thin film layers.

- Cell-to-Cell Bonding: Provides optimal thermal conditions for bonding processes in solar cell assembly.

Frequently Asked Questions

What is Accuflect IR?

What are the applications of Accuflect IR?

What are the advantages of using Accuflect IR in solar cell fabrication processes?

What is the peak emission wavelength of Accuflect IR?

What are some of the infrared systems that can be used with Accuflect IR?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle