Description

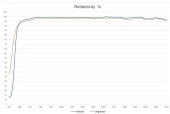

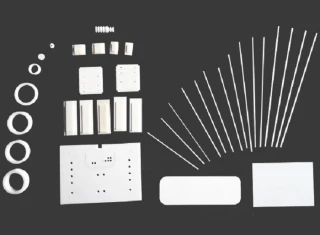

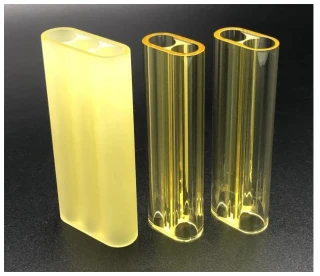

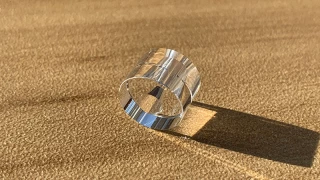

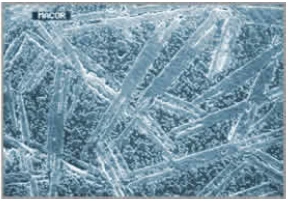

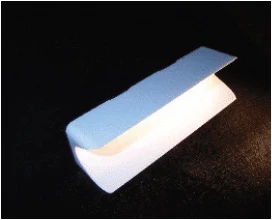

Introducing our advanced Ceramic Reflector, a high-quality focusing cavity material that stands out due to its exceptional diffuse reflection characteristics, robust mechanical properties, and superior chemical structural stability. These ceramic materials are designed to provide a more uniform irradiation light field on the laser working substance, ensuring an even pump across the entire cross-section. This uniformity is crucial for optimizing laser performance and efficiency. Ceramic Reflectors are crafted from alumina ceramic, known for its impressive physical properties. These reflectors boast a fully glazed surface, which not only enhances their reflectivity but also makes them easy to clean. The glazing process ensures that the reflectivity reaches up to 98% at wavelengths of 600-1000 nm, and exceeds 96% in the frequency range of 400-1200 nm. Such high reflectivity is essential for maximizing the effectiveness of lamp-pumped solid-state lasers, which are widely used in various industries including medical, welding, cutting, and marking. The durability of our Ceramic Reflector is unmatched, thanks to its high-strength characteristics and appropriate porosity. It offers a long service life, making it a reliable choice for demanding applications. With a bulk density of 3.1 g/cm³ and a purity level exceeding 99%, this product is engineered to withstand rigorous conditions. Its thermal shock resistance allows it to endure cycles from 15-100°C without cracking, and it features a thermal expansion coefficient suitable for a wide range of temperatures. Our standard Ceramic Reflectors are available in various sizes, all featuring full glazing for optimal performance. Whether you require a specific dimension or need a custom solution, our team is ready to assist you in selecting the right product to meet your needs.

Ceramic Reflector for Lamp-Pumped Solid-State Lasers

Specifications

| Material: | Aluminum Nitride, Ceramic |

|---|---|

| Type Of Ceramic: | Unglazed, Glazed |

| Component Type: | Reflectors |

| Material: | alumina ceramic |

| Color: | White |

| Bulk Density (fired): | 3.1 g/cm³ |

| Porosity (apparent): | 30±1% |

| Purity: | >99% |

| Reflectivity: | See the following figure for details |

| Surface Treatment: | glazing |

| Flexural Strength: | 170 MPa |

| Thermal Shock Resistance: | 15-100°C Cycle 50 times no cracks |

| Thermal Expansion Coefficient (200-500°C): | 7.9×10⁻⁶/°C |

| Thermal Expansion Coefficient (200-1000°C): | 9×10⁻⁶/°C |

Features

- High Reflectivity and Easy Cleaning: The ceramic reflector features a fully glazed surface that provides high reflectivity and facilitates easy cleaning.

- Excellent Reflectivity Range: Achieves 98% reflectivity at wavelengths of 600-1000 nm and exceeds 96% reflectivity in the frequency range of 400-1200 nm.

- Durable Material: Constructed from high-purity alumina ceramic with a purity greater than 99%, ensuring long service life and robust performance.

- Mechanical Strength: The ceramic blank is designed with appropriate porosity and high strength characteristics, offering a flexural strength of 170 MPa.

- Thermal Shock Resistance: Can withstand thermal shock cycles from 15°C to 100°C for 50 cycles without cracking.

- Applications: Ideal for lamp-pumped solid-state lasers used in medical, welding, cutting, and marking applications.

Applications

- Lamp pumped solid-state systems used in

- Medical lasers

- Laser welding machines

- Cutting machines

- Marking machines

Frequently Asked Questions

What is the Ceramic Reflector used for?

What are the key features of the Ceramic Reflector?

What material is the Ceramic Reflector made of?

What is the reflectivity range of the Ceramic Reflector?

What are the physical properties of the Ceramic Reflector?

What sizes are available for the Ceramic Reflector?

How does the Ceramic Reflector improve laser performance?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle