Description

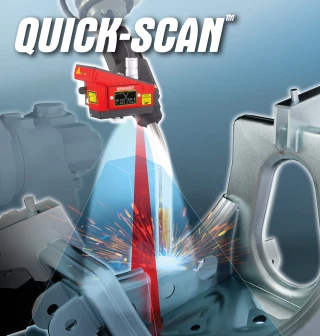

Introducing the i-CUBE-T family, a groundbreaking advancement in intelligent robotic sensing systems designed specifically for welding robots. This innovative series, including the i-CUBE-T 100 L and i-CUBE-T 350 L, represents a leap forward in automation technology, offering unparalleled precision and efficiency in industrial applications. The i-CUBE-T systems are engineered to enhance the capabilities of welding robots, ensuring seamless integration and superior performance.

At the core of the i-CUBE-T family is its remarkable ability to perform very high-speed seam finding and high-speed joint and part location. These features enable the system to quickly and accurately identify welding seams and joints, significantly reducing downtime and increasing productivity. The i-CUBE-T systems are equipped with remote distance seam tracking, allowing for precise monitoring and adjustment from afar, which is crucial for maintaining quality and consistency in welding operations.

The i-CUBE-T series also boasts a powerful on-board control system, providing robust processing capabilities that support complex welding tasks. This control system is complemented by advanced process monitoring features, which ensure that every aspect of the welding process is meticulously tracked and optimized. The intelligent design of the i-CUBE-T systems allows for seamless integration with existing robotic setups, enhancing their functionality and extending their operational lifespan.

Designed with the future of automation in mind, the i-CUBE-T family is an essential component for any modern welding operation. Its intelligent robotic sensing capabilities not only improve the accuracy and speed of welding tasks but also contribute to a safer and more efficient working environment. Embrace the future of welding technology with the i-CUBE-T series and experience the difference in performance and reliability.

i-CUBE-T Robotic Sensing System for Welding Robots

Specifications

| Working Distance: | 100 – 350 mm |

|---|---|

| Max Temperature: | 50 degC |

| Sensor Type: | Universal Robot Sensor with multi-sensing integration |

| Measurement Technology: | 3D multi-laser range imaging optics |

Features

- Very High-Speed Seam Finding: Achieve precise and rapid seam detection for enhanced efficiency.

- High-Speed Joint and Part Location: Quickly locate joints and parts to streamline your welding processes.

- Remote Distance Seam Tracking: Maintain accuracy with advanced remote seam tracking capabilities.

- Powerful On-Board Control: Benefit from robust control systems integrated directly into the unit.

- Process Monitoring: Keep track of welding processes with comprehensive monitoring features.

- Intelligent Robotic Sensing System for Welding Robots: Enhance your robotic welding operations with intelligent sensing technology.

Applications

- Arc Seam Finding: Ensures accurate joint detection for welding automation.

- Material Handling: Enhances precision in part location, alignment, and manipulation.

- Plasma Cutting & Beveling: Delivers reliable edge detection and cutting path accuracy.

- Automatic Robot Teaching: Simplifies programming through sensor-guided learning.

- Seam Tracking & Process Monitoring: Maintains real-time accuracy in dynamic environments.

- Industrial Inspection: Enables quality assurance with integrated video and sensor data.

Frequently Asked Questions

What is i-CUBE?

What functions does i-CUBE integrate?

What are the key features of i-CUBE?

Does i-CUBE require an external controller?

What industrial applications is i-CUBE suitable for?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle