Description

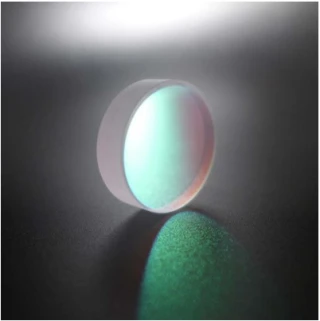

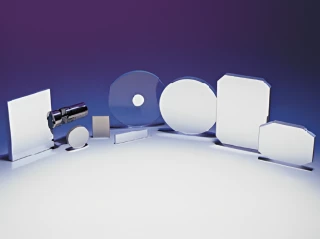

Circular, Square, Rectangular Mirrors from Tower Optical are crafted with precision and quality, ensuring that each piece meets the highest standards of optical performance. These mirrors are designed with a highly polished surface that effectively reflects light, making them ideal for various optical applications. The reflecting surface is typically coated with a thin layer of aluminum or silver, which is applied to the front surface. This first surface coating technique eliminates the optical properties of the glass from affecting the incident or reflected light, ensuring clarity and precision in reflection.

Each mirror features a protected aluminum coating on the front surface, providing durability and longevity. The rear surface is finely ground to enhance the mirror's overall quality. Tower Optical offers mirrors in different grades, including Standard and High Grade, to cater to diverse needs. The Standard Grade mirrors are made from BK7 grade A optical glass, while the High Grade mirrors are available in BK7 grade A or fused silica, offering superior optical performance.

At Tower Optical, we understand that every project is unique. That's why we offer custom versions of all our mirrors. Simply send us your drawings or specifications, and we will provide a tailored quotation to meet your specific requirements. Our commitment to quality and customer satisfaction is reflected in every product we create, ensuring that you receive mirrors that are not only functional but also reliable and precise.

UV Grade Fused Silica Mirror and High Grade MF22-020

Specifications

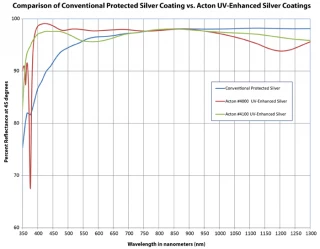

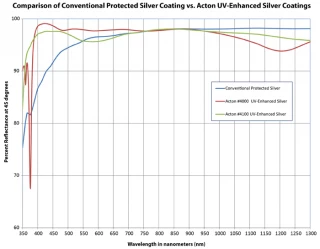

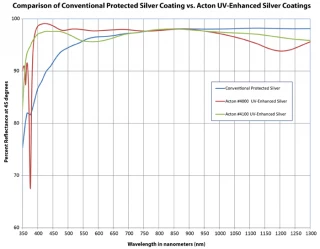

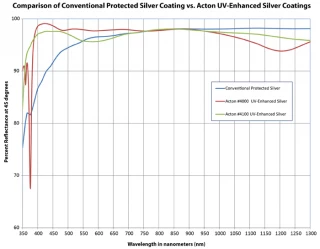

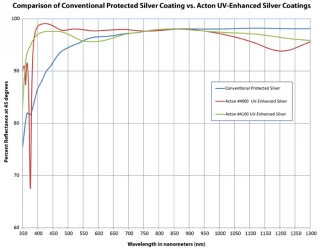

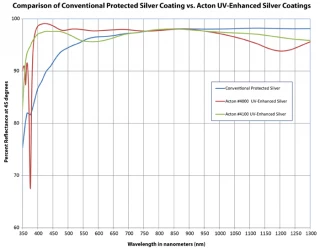

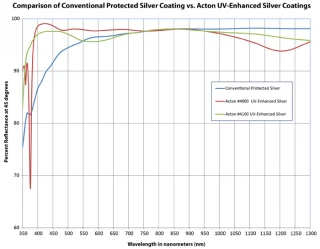

| Reflective Coating: | Protected Silver, Protected Aluminum |

|---|---|

| Substrate: | UV Fused Silica |

| Average Reflectance: | 95 % |

| Wavelength Range: | 500 – 1000 nm |

| Surface Flatness: | lambda/10 |

| Surface Quality: | 10-5 scratch-dig |

| Diameter: | 20 mm |

| Thickness: | 6 mm |

| Shape: | Round, Square |

Features

- High-Quality Reflective Surface: All mirrors feature a highly polished surface with a front surface aluminum coating, ensuring optimal light reflection and eliminating interference from the glass substrate.

- Material Options: Available in BK7 Grade A optical glass for both standard and high-grade mirrors, and UV Grade Fused Silica for high-grade mirrors.

- Dimensional Precision: Both standard and high-grade mirrors maintain a dimensional tolerance of +0.0/-0.1mm, ensuring precise measurements for your optical applications.

- Flatness: Standard grade mirrors offer λ/5 @ 632.8nm flatness, while high-grade mirrors provide superior λ/10 @ 632.8nm flatness for enhanced optical performance.

- Surface Quality: The mirrors feature a scratch/dig surface quality of 40/20 for standard grade and 10/5 for high-grade, ensuring minimal surface imperfections.

- Thickness Tolerance: All mirrors have a thickness tolerance of ±0.2mm, providing consistency across different models.

- Parallelism: Both grades offer parallelism of less than 3 arc minutes, ensuring precise alignment in optical systems.

- Custom Options Available: Custom versions of all mirrors can be made to your specifications. Simply send your drawings or requirements for a quotation.

Applications

- Laser Systems: Provides precise beam reflection and alignment in optical setups.

- Imaging & Projection: Ensures high-quality, distortion-free reflections in cameras and display systems.

- Spectroscopy Instruments: Maintains wavelength accuracy for analytical applications.

- Scientific Research: Suitable for laboratory experiments requiring precision optics.

- Custom Optical Assemblies: Adaptable to specialized industrial and R&D projects.

Frequently Asked Questions

What is a UV Grade Fused Silica Mirror?

What are the dimensions of the mirror?

What is the surface quality of the mirror?

What is the thickness tolerance of the mirror?

What is the parallelism of the mirror?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle