Description

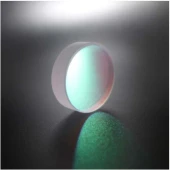

SPAWR Industries, Inc. is renowned for its exceptional quality in the production of metal mirrors, specifically designed for high-energy laser applications. Located in Lake Havasu City, AZ, SPAWR has established itself as a leading supplier of state-of-the-art metal mirrors, offering unparalleled surface damage thresholds for medium and long wave infrared lasers. The uncoated copper mirrors produced by SPAWR are crafted to meet the highest standards, ensuring optimal performance without the necessity for additional high reflectance coatings. However, for those requiring enhanced reflectivity, options such as vacuum deposited protected silver or electrochemically deposited hard gold coatings are available.

SPAWR's mirrors are meticulously engineered to cater to the demanding requirements of very high-power laser research. The optical characteristics of these mirrors are optimized for 80% of the mirror's diameter, with a standard wavelength of 10.6 micrometers. The mirrors are available in various standard radii, including concave options of 1M, 5M, 10M, and 20M, suitable for diameters up to 4 inches. For larger mirrors exceeding 16 inches in diameter, SPAWR offers custom solutions tailored to specific needs, with quotes available upon request.

Each mirror is accompanied by a protective shipping and storage container, ensuring safe transportation and longevity. Notably, the 12-inch and 16-inch diameter mirrors feature a lightweight ribbed structure, enhancing their practicality and ease of handling. SPAWR's commitment to quality is evident in the precise specifications of their mirrors, which boast a reflectivity of 99% at 10.6 micrometers, surface accuracy, and smoothness that meet stringent laboratory and industrial grade standards. Constructed from high purity copper, these mirrors are designed to withstand the rigors of high-power laser applications, making them an indispensable component for researchers and industry professionals alike.

LCu-015 High Purity Copper Mirrors for Medium and Long Wave IR Lasers

Specifications

| Reflective Coating: | Custom |

|---|---|

| Substrate: | Custom |

| Average Reflectance: | 99 % |

| Wavelength Range: | 1 – 1 nm |

| Surface Flatness: | lambda/20 |

| Surface Quality: | 20-10 scratch-dig |

| Diameter: | 38.1 mm |

| Thickness: | 6.4 mm |

| Shape: | Round |

Features

- High Energy Laser Compatibility: SPAWR's uncoated copper mirrors are designed for medium and long wave IR lasers, offering the highest quality and surface damage threshold available.

- Reflectivity: Laboratory Grade mirrors provide 99% reflectivity at 10.6 µm, ensuring optimal performance for high-power laser applications.

- Surface Accuracy and Smoothness: Laboratory Grade mirrors feature a surface accuracy of λ/20 and a surface smoothness of 30Å RMS, while Industrial Grade mirrors offer λ/10 accuracy and 45Å RMS smoothness.

- Scratch/Dig Specifications: Laboratory Grade mirrors have a scratch/dig rating of 20/10, and Industrial Grade mirrors have a rating of 60/40, ensuring minimal surface imperfections.

- Damage Threshold: Laboratory Grade mirrors withstand >2.5 x 102 J/cm2 s, and Industrial Grade mirrors withstand 10 J/cm2 s, making them suitable for high-power applications.

- Material: Made from high purity copper, these mirrors ensure durability and performance in demanding environments.

- Custom Sizes Available: Mirrors larger than 16” diameter, including custom designs, are available upon request.

- Protective Packaging: Each mirror is shipped in a protective container to ensure safe storage and transportation.

- Lightweight Design: The 12” and 16” diameter mirrors feature a lightweight ribbed structure for ease of handling and installation.

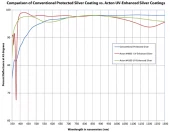

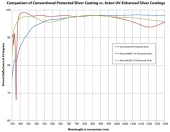

- Optional Coatings: High reflectance coatings are available as vacuum deposited protected silver or electrochemically deposited hard gold, although typically not required.

Applications

- CO₂ Laser Systems: Ideal for high-energy IR laser research and processing.

- Industrial Laser Processing: Cutting, welding, and material treatment with high reliability.

- Laboratory Research: Precision optics for advanced high-power laser experiments.

- Custom Optical Systems: Adaptable designs for unique geometries and radii requirements.

- Inspection and Quality Control: Reference-grade optics for testing and calibration.

Frequently Asked Questions

Are high reflectance coatings required on these mirrors?

What are copper mirrors used for?

What are the optical characteristics of these mirrors?

What is the approximate weight of the mirrors?

What is the damage threshold of these mirrors?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle