Description

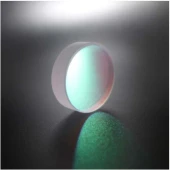

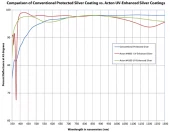

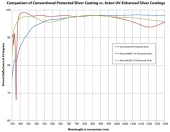

SPAWR Industries is a renowned leader in the production of high-quality metal mirrors, specifically designed for high-energy laser applications. Located in Lake Havasu City, Arizona, SPAWR Industries has been at the forefront of innovation in the field of laser optics since 2002. Our uncoated copper mirrors are engineered to offer the highest surface damage threshold available, making them ideal for medium and long wave infrared (IR) lasers. While high reflectance coatings are not typically necessary for these mirrors, we do offer options such as vacuum deposited protected silver and electrochemically deposited hard gold coatings for enhanced performance.

Our copper mirrors are crafted with precision to meet the rigorous demands of high-power laser research. SPAWR's mirrors are known for their exceptional optical characteristics, covering 80% of the mirror's diameter with a wavelength of 10.6 micrometers. We offer standard concave radii of 1M, 5M, 10M, and 20M for mirrors up to 4 inches in diameter. For larger mirrors, including custom sizes beyond 16 inches in diameter, we provide tailored solutions upon request. Each mirror is accompanied by a protective shipping and storage container to ensure its integrity during transit.

Our product line includes both laboratory and industrial grade mirrors, each designed to meet specific application needs. Laboratory grade mirrors boast a reflectivity of 99% at 10.6 micrometers, with surface accuracy of /20 and a smoothness of 30Å RMS. Industrial grade mirrors offer similar reflectivity with slightly different specifications, ensuring a balance between performance and cost-effectiveness. Both grades are manufactured from high purity copper, ensuring durability and reliability in demanding environments.

SPAWR Industries is committed to providing state-of-the-art solutions for the laser industry, backed by years of expertise and a dedication to quality. Our mirrors are not just components; they are critical elements in the advancement of laser technology, trusted by researchers and professionals worldwide.

LCu-001 High Purity Copper Mirrors for Medium and Long Wave IR Lasers

Specifications

| Reflective Coating: | Custom |

|---|---|

| Substrate: | Custom |

| Average Reflectance: | 99 % |

| Wavelength Range: | 1 – 1 nm |

| Surface Flatness: | lambda/20 |

| Surface Quality: | 20-10 scratch-dig |

| Diameter: | 25.4 mm |

| Thickness: | 6.4 mm |

| Shape: | Round |

Features

- High-Quality Copper Mirrors: SPAWR Industries offers uncoated copper mirrors that provide the highest quality and surface damage threshold for medium and long wave IR lasers.

- Reflectivity: Laboratory Grade mirrors offer 99% reflectivity at 10.6 µm, while Industrial Grade mirrors also provide 99% reflectivity at 10.6 µm.

- Surface Accuracy and Smoothness: Laboratory Grade mirrors have a surface accuracy of λ/20 and a smoothness of 30Å RMS. Industrial Grade mirrors have a surface accuracy of λ/10 and a smoothness of 45Å RMS.

- Scratch/Dig Specifications: Laboratory Grade mirrors feature a 20/10 scratch/dig specification, while Industrial Grade mirrors have a 60/40 specification.

- Damage Threshold: Laboratory Grade mirrors have a damage threshold of >2.5 x 102 J/cm2, while Industrial Grade mirrors have a threshold of 10 J/cm2.

- Material: Both grades are made from high purity copper, ensuring durability and performance.

- Standard Radii: Available in concave radii of 1M, 5M, 10M, and 20M for mirrors up to 4” in diameter.

- Custom Sizes Available: Mirrors larger than 16” in diameter, including custom mirrors, are available upon request.

- Protective Packaging: Each mirror comes with a protective shipping/storage container to ensure safe transport and storage.

- Lightweight Design: The 12” and 16” diameter mirrors feature a lightweight ribbed structure for ease of handling.

Applications

- High-Power CO₂ Laser Systems: Reliable optics for cutting, welding, and materials processing.

- Laser Research Laboratories: Ultra-precise mirrors for high-energy IR laser experiments.

- Industrial Manufacturing: Durable performance in demanding laser-based production environments.

- Custom Optical Assemblies: Adaptable to specialized geometries, radii, and coatings.

- Quality Control & Testing: Benchmark optics for calibration and inspection systems.

Frequently Asked Questions

Are high reflectance coatings necessary for copper mirrors?

What are copper mirrors used for?

What are the optical characteristics of copper mirrors?

What are the standard radii for copper mirrors?

What is the approximate weight of the copper mirrors?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle