Description

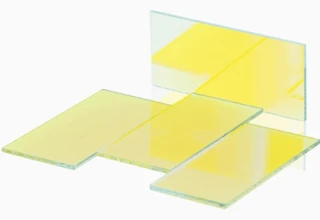

450nm Hard Film Longpass Optical Filter

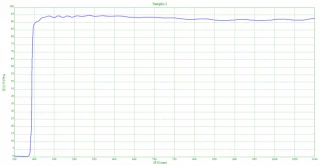

One of our standout products is the 450nm Long Pass Filter. This longpass filter is meticulously designed and manufactured to provide superior performance and reliability. By utilizing advanced hard film coating techniques, we ensure that our filters offer long service life and exceptional wavelength accuracy. The filter's ion plating further enhances its stability, minimizing temperature drift and maintaining consistent performance under varying conditions.

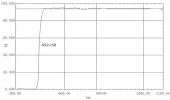

Our 450nm Longpass Filter is constructed from high-quality raw materials such as Fused Silica, B270, and Float Glass, among other optical glasses. This choice of materials guarantees high penetration rates and remarkable cut-off depth. The filter is designed to allow wavelengths from 460nm to 1100nm to pass through, with a transmission rate exceeding 95%, while effectively blocking unwanted wavelengths with a cut-off rate of less than 0.05%. These attributes make our longpass filter an essential component for applications requiring precise optical filtration.

Shandong Yanggu Constant Crystal Optics, Inc. has been a pioneer in the field of optical glass components manufacturing since 2006. With a commitment to precision and quality, our products are crafted to meet the highest industry standards. Our expertise in optical solutions is evident in every component we produce, ensuring they are at the forefront of technology and innovation. At Shandong Yanggu Constant Crystal Optics, Inc., we pride ourselves on our dedication to quality and innovation. Our products, including the 450nm Longpass Filter, are a testament to our commitment to excellence in the optical industry.

450nm Hard Film Longpass Optical Filter

Specifications

| Transmission Wavelength Range: | 460 – 1100 nm |

|---|---|

| Cut-On Wavelength: | 440 nm |

| Transmission: | 95 % |

| Blocking (Optical Density): | OD>=3 |

| Filter Type: | Longpass Filter |

| Coating Type: | Hard film Coated |

| AOI: | 0°±5° |

| Central Wavelength: | 450nm±3nm |

| Cutoff Wavelength: | 200nm~440nm |

| Cutoff Rate: | <0.05% |

| Passing Wavelength: | 460nm~1100nm |

| Transmission: | >95% |

| Scratch-Dig: | 60/40 |

| Raw Material: | Fused Silica, B270, Float Glass, or other optical glass |

Features

- Raw Material: Fused Silica, B270, Float Glass, or other optical glass

- Advantages:

- Plated with hard, long service life

- Wavelength accuracy

- Ion plating, low temperature drift

- High penetration rate

- High cut-off depth

Applications

- Optical Instrumentation: Ideal for use in spectrometers and other optical instruments that require precise wavelength filtering.

- Medical Imaging: Suitable for enhancing image quality in medical imaging devices by filtering out unwanted wavelengths.

- Photography and Videography: Used in camera lenses and filters to improve image clarity and color accuracy.

- Scientific Research: Applicable in various research fields requiring specific wavelength transmission, such as fluorescence microscopy.

- Telecommunications: Used in optical communication systems to manage signal wavelengths.

- Laser Applications: Essential in laser systems for cutting, engraving, or medical procedures where specific wavelength control is necessary.

- Environmental Monitoring: Utilized in devices that monitor environmental conditions by filtering specific wavelengths.

- Consumer Electronics: Integrated into devices like projectors and displays to enhance visual output quality.

Frequently Asked Questions

What is the main function of the 450nm longpass filter?

What materials are used for this filter?

What is the transmission rate of the filter for passing wavelengths?

What is the cutoff wavelength range for this filter?

What is the advantage of the hard film coating on this filter?

What is the acceptable angle of incidence (AOI) for this filter?

What is the scratch-dig specification for this filter?

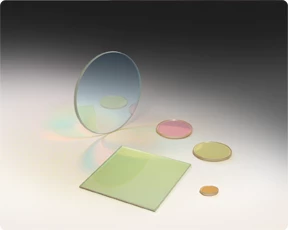

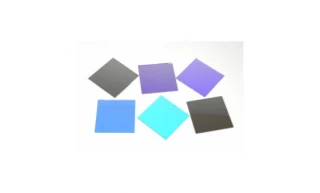

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle