Description

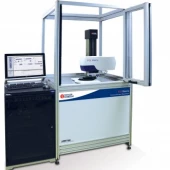

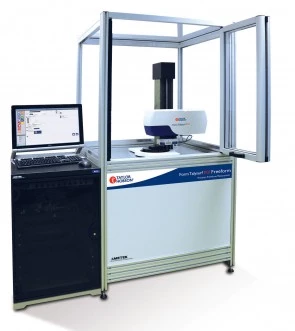

The Taylor Hobson Form Talysurf® PGI Matrix is a fully automated, high-speed, and highly accurate system designed for precision measurement of optical components. Ideal for both single-part and batch testing, it streamlines the measurement process with easy set-up, automated alignment, and instant analysis.

Combining the renowned accuracy of PGI technology with fast motorized stages and an intuitive software interface, the system ensures reliable results even in high-volume production environments. Advanced features such as automated spike removal, P-V/RMS radius optimization, and cycle-time calculators maximize efficiency while maintaining repeatable, traceable measurements.

The integrated Aspherics Analysis Utility (AAU) software delivers rapid evaluation of form error, slope, radius, zone depth, and spacing, and can extract sub-micron lens form errors even from large diffractive features. Derived coefficient functions support reverse engineering, providing valuable feedback to optical designers for process optimization.

Designed for industrial environments, the system includes pneumatic anti-vibration mounts, a motorized column for large sample sizes, and a UKAS-calibrated electrical and PC cabinet. Its fully automated operation and production-focused software make the Form Talysurf® PGI Matrix the complete solution for precision optics metrology.

Form Talysurf PGI Matrix

Specifications

| Measurement Technique: | Other (not specified) |

|---|---|

| Light Source Type: | Coherent Continuous Wave (CW) |

| Sample Reflectivity: | 1 – 1 % |

| RMS Repeatability: | <0.001 nm |

| RMS Precision: | <0.001 nm |

| Magnification: | Other / Not specified |

| Application: | 3D Imaging |

| Software Compatibility: | Other / Not specified |

| Z-axis Sensing Technology: | Not Specified |

Features

- Fully Automated Measurement: Motorized stages and software enable single or batch part analysis.

- High Accuracy: Nanometer-level form error measurement with PGI technology.

- Fast, Repeatable Results: Automated alignment, spike removal, and radius optimization ensure reliable outputs.

- Advanced Analysis Software: AAU software calculates form error, slope, radius, zone depth, and spacing.

- Reverse Engineering Capabilities: Derived coefficient functions provide feedback to designers for performance optimization.

- Industrial-Ready Design: Pneumatic anti-vibration mounts, motorized columns, and a UKAS-calibrated cabinet.

- Ease of Use: Intuitive interface simplifies programming and measurement cycles, even in high-volume production.

Applications

- Plastic and Glass Lenses: High-speed, accurate quality verification.

- Diffractive Optics: Measurement and analysis of complex surface geometries.

- High-Volume Production: Batch measurement for efficient manufacturing.

- Optical Component Reverse Engineering: Feedback for design adjustment and process optimization.

- Industrial Metrology: Reliable surface texture and form analysis under production conditions.

Frequently Asked Questions

What are the features of the Form Talysurf PGI Matrix?

What is Taylor Hobson?

What is the difference between Form Talysurf PGI Dimension and Form Talysurf PGI Matrix?

What is the Form Talysurf PGI Matrix used for?

What is the LuphoScan used for?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle