Description

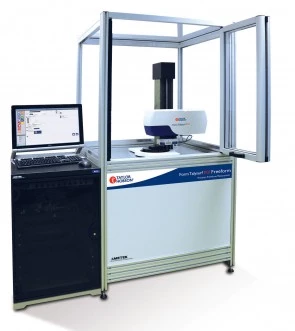

The Taylor Hobson Form Talysurf® PGI Optics is the industry-standard solution for the precise measurement of aspheric and diffractive optics. Since its introduction in 1984, it has become the benchmark system for global optics manufacturers, delivering unmatched form accuracy, repeatability, and measurement reliability.

Powered by Taylor Hobson’s patented PGI technology, the system enables the measurement of large sags using short-length styli, combining high stiffness with low force for superior accuracy and reproducibility compared to conventional systems. With a gauge range of up to 28 mm, noise levels below 2 nm Rq, and form error measurement capability of less than 100 nm on optics up to 300 mm in diameter, it is ideally suited for demanding next-generation applications.

The advanced software interface makes programming and analysis simple, with automated cresting, spike removal, and radius optimization ensuring traceable, repeatable results. Additional tools such as sag and slope calculators, reverse engineering functions, and feedback algorithms streamline manufacturing processes, reduce costs, and improve yields.

Designed for versatility, the Form Talysurf® PGI Optics is available in multiple instrument sizes and software packages, making it the complete metrology solution for modern optics manufacturing and research.

Form Talysurf PGI Optics

Specifications

| Measurement Technique: | Other (not specified) |

|---|---|

| Light Source Type: | Coherent Continuous Wave (CW) |

| Light Source Wavelength: | 2 nm |

| Sample Reflectivity: | 1 – 1 % |

| RMS Repeatability: | <0.001 nm |

| RMS Precision: | <0.001 nm |

| Magnification: | Other / Not specified |

| Application: | 3D Imaging |

| Software Compatibility: | Other / Not specified |

| Z-axis Sensing Technology: | Not Specified |

Features

- Patented PGI Technology: Measures large sags with short styli, ensuring maximum stiffness and accuracy.

- High Precision Performance: Gauge range up to 28 mm with noise below 2 nm Rq.

- Exceptional Form Accuracy: Capable of form error measurement under 100 nm for optics up to 300 mm in diameter.

- Automated Analysis Tools: Features cresting, spike removal, and radius optimization for repeatable results.

- Advanced Software Algorithms: Includes sag/slope calculators, reverse engineering, and feedback functions for process optimization.

- Easy-to-Use Interface: Intuitive programming and automated analysis minimize operator error and reduce training costs.

Applications

- Plastic Lenses: Accurate form measurement for high-volume consumer optics.

- Diffractive Optics: Ensures precision in complex optical surface validation.

- IR Glass and Crystals: Optimized for infrared optical component manufacturing.

- Large Diameter Optics: Measures optics up to 300 mm without compromising accuracy.

- Small Optical Components: Provides high-resolution measurement for miniature precision optics.

Frequently Asked Questions

What are the recent developments by Taylor Hobson?

What is PGI technology?

What is the difference between LuphoScan and Form Talysurf PGI Optics?

What is the Form Talysurf PGI Optics used for?

What is the maximum diameter of optics that can be measured using Form Talysurf PGI Optics?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle