Description

MESO metrology system is a one-stop solution to many challenges in optical metrology. Shop floor measurements ensure quality control testing and in situ process control of your flat optics right next to the manufacturing line.

A unique instrument allows to measure at several different wavelengths with no chromatic abberrations and to characterize the whole range of your optics with no loss of resolution.

MESO™ is packed with innovation:

- LIFT-enhanced high wavefront sensing resolution

- POP-patent pending procedure for the testing of (thin) plane parallel optics

- Spot Tracker™ proprietary technology provides absolute measurement of tilt and wavefront.

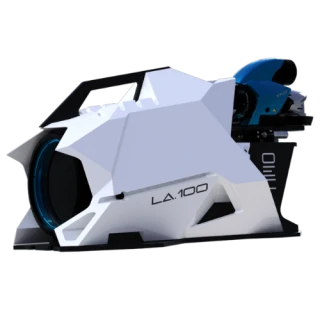

MESO Metrology System

Specifications

| Interferometer Configuration: | Not Specified |

|---|---|

| Light Source: | 543nm, 594nm, 632 nm or 633nm, 780nm, 532nm |

| Output Polarization: | Linear, Circular |

| RMS Repeatability: | <0.01 waves |

| RMS Precision: | <0.01 waves |

| Optical Axis: | text 108 mm |

| Dimensions: | text 63 x 30 x 45 cm |

| Phase Point Resolution: | text 680 x 500 |

| Test Beam Diameter: | text Optical zoom from 1.5″ (38.1mm) up to 6″ (152 mm) |

| Calibrated Range: | text 405 nm to 830 nm |

| Wavelength: | text Custom 405, 488, 520, 635, 785, 830 nm |

Features

- Insensitive to vibrations

- At-design wavelength testing

- Insensitive to reflections from sample back surface

Applications

MESO is the perfect testing tool for the control of:

- Parallel Optics

- Screens

- Filters, dichroics

- Mirrors

- Beamsplitters

- Windows

- Substrates

- Corner cubes

- Crystals

- Rods, Disks

- Glass wafers

- Displays

- Machined surfaces

- Windshields

- Prisms

- Large lenses

- Optical systems

- Beam expanders

Frequently Asked Questions

What is the MESO metrology system used for?

The MESO metrology system is used for optical metrology, specifically for quality control testing and in situ process control of flat optics.

What are the unique features of the MESO metrology system?

The MESO metrology system has features such as LIFT-enhanced high wavefront sensing resolution, a POP-patent pending procedure for testing thin plane parallel optics, and Spot Tracker™ proprietary technology for absolute measurement of tilt and wavefront.

Is the MESO metrology system sensitive to vibrations?

No, the MESO metrology system is insensitive to vibrations, making it suitable for shop floor metrology.

Can the MESO metrology system measure at different wavelengths?

Yes, the MESO metrology system can measure at several different wavelengths with no chromatic aberrations.

What are some of the applications of the MESO metrology system?

The MESO metrology system is used for testing parallel optics, screens, filters, mirrors, beamsplitters, windows, substrates, corner cubes, crystals, rods, disks, glass wafers, displays, machined surfaces, windshields, prisms, large lenses, and optical systems.

Similar Products

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle