Description

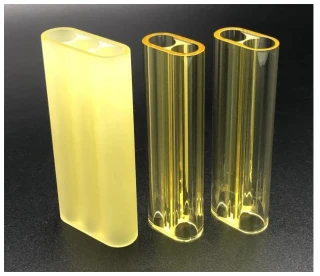

Elevate your laser's performance with ARD Optics’ Laser Flow Tubes and Reflectors. Specifically designed for water-cooled lamp-pumped lasers, our laser flow tubes protect the laser elements from undesired UV radiation, absorbing it to enhance the efficiency of your laser system. Manufactured from materials like Pyrex Glass, Borofloat, Fused Silica, and Doped Glasses, our flow tubes and reflectors are precision-engineered for optimum performance. We also offer customizable options for reflectors with flow tubes provided by the customer. Optimize your laser cavity with ARD Optics.

Precision Laser Flow Tubes & Reflectors for Water-Cooled Lasers | Ard Optics

Specifications

| Material: | Fused Silica, UV Fused Silica, BK7, Sapphire, Zerodur, Doped Glass |

|---|---|

| Type Of Ceramic: | Other |

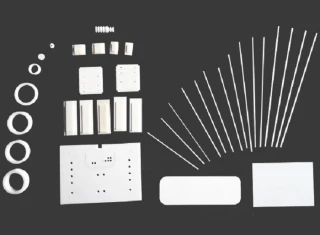

| Component Type: | Reflectors, Rods, Tubes, Flowtubes, Reflectors, Specular Reflectors, Lightguides |

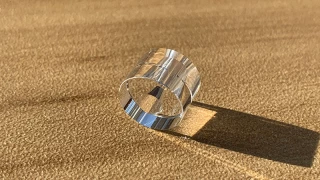

| Holes Diameter Range: | From 2mm to 40mm with tolerances of +/-0.05 to 0.1mm |

| Length Range: | From 10mm to 150mm with tolerances of +/-0.05 to 0.1mm |

| Parallelism Of Holes: | 0.05 to 0.1 mm |

| Customization Options: | Ability to produce reflectors with the flow tube provided by the customer |

Features

- Enhanced Laser Efficiency: Effectively absorbs UV radiation and side emissions to enhance laser performance.

- Diverse Material Selection: Manufactured from Pyrex Glass, Borofloat 33, Fused Silica, Cerium Doped Fused Silica, and Samarium Doped Glass (S7005 (5%Sm), S7010 (10%Sm)).

- Protection: Safeguards laser elements from undesired UV radiation.

- Customization Available: ARD Optics can produce reflectors with the flow tube provided by the customer.

- Precision Engineering: Ensures high accuracy and reliability in laser applications.

- Versatile Components: Including reflectors, light guides, specular reflectors, flow tubes, tubes, and rods.

Applications

- Lamp-Pumped Lasers: Optimizes the performance of water-cooled lamp-pumped lasers by protecting laser elements and enhancing efficiency.

- Industrial Laser Cutting: Ideal for use in industrial laser cutting machines for precise and efficient cutting.

- Medical Lasers: Utilized in medical lasers for treatments and surgeries.

- Laser Marking & Engraving: Employed in laser marking and engraving systems for high accuracy and performance.

- Scientific Research: Useful in laboratory lasers used in research and development.

- Defense & Security: Applied in lasers used for targeting, range-finding, and defense applications.

Frequently Asked Questions

What are the benefits of using ARD Optics Laser Flow Tubes?

ARD Optics Laser Flow Tubes enhance the efficiency of lasers by absorbing undesired UV radiation and side emissions, protecting the laser elements, and improving overall performance.

What materials are ARD Optics Laser Flow Tubes made from?

They are manufactured from a variety of materials including Pyrex Glass, Borofloat 33, Fused Silica, Cerium Doped Fused Silica, and Samarium Doped Glass.

Can ARD Optics produce custom Laser Reflectors?

Yes, ARD Optics offers customization options and can produce laser reflectors with the flow tube provided by the customer.

What components are included in the ARD Optics laser product range?

The product range includes Reflectors, Lightguides, Specular Reflectors, Flow Tubes, Tubes, and Rods for laser applications.

What are the dimensions of the holes and lengths of ARD Optics Laser Reflectors?

The holes in the reflectors range in diameter from 2mm to 40mm, and the lengths range from 10mm to 150mm, with high precision tolerances.

Are ARD Optics Laser Flow Tubes suitable for industrial applications?

Absolutely! ARD Optics Laser Flow Tubes are ideal for various industrial applications including laser cutting, marking, and engraving due to their high precision and efficiency.

Can these Laser Flow Tubes and Reflectors be used in scientific research?

Yes, the precision and performance of ARD Optics Laser Flow Tubes and Reflectors make them suitable for scientific research and laboratory lasers.

What type of ceramic is used in ARD Optics Laser Flow Tubes?

The type of ceramic is not specified, but ARD Optics uses high-quality materials to ensure optimal performance in laser applications.

What are laser flow tubes used for?

Laser flow tubes are used to protect laser elements from undesired UV radiation and absorb emissions from the side of the rod, thus enhancing the efficiency of the laser.

What materials are laser flow tubes made from?

Laser flow tubes can be made from Pyrex Glass, Borofloat 33, Fused Silica, Cerium Doped Fused Silica, and Samarium Doped Glass S7005 (5%Sm), S7010 (10%Sm).

What is the purpose of reflectors for laser cavity?

Reflectors for laser cavity are used to reflect light back and forth through the laser gain medium, amplifying the light and producing a laser beam.

What are the specifications for laser flow tubes?

Laser flow tubes have a diameter of +/-0.05-0.1 mm and a length of +/-0.05-0.1 mm, with a parallelity of holes of 0.05-0.1 mm.

Can ARD Optics produce reflectors with a flow tube provided by the customer?

Yes, ARD Optics can produce reflectors with a flow tube provided by the customer.

Similar Products

99.5% BeO Ceramic Substrate Manufacturer/High Thermal Low Dielectric Beryllium Ceramic Substrate For RF Microwave Package

Coraynic Technology Limited

Quartz Reflector for Laser Applications

CRYSTECH Inc.

Ceramic Reflector for Lamp-Pumped Solid-State Lasers

CRYSTECH Inc.

Optical-Grade Sapphire Optics with Superior Edge Quality and Custom Shapes

Walthy Precision Co., Ltd.

Custom Ceramics Micro Washers and Parts

Walthy Precision Co., Ltd.

Custom Sapphire Parts

Walthy Precision Co., Ltd.

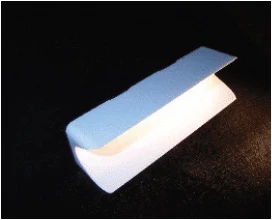

Custom-Made Laser Components | Flow Tubes and Reflectors by ARD Optics

ARD-OPTICS

Customizable Specular Silver Coated Reflectors for Diode-Pumped Lasers by ARD Optics

ARD-OPTICS

Accuflect IR Solar Cell Furnace Reflector

Accuratus Corporation

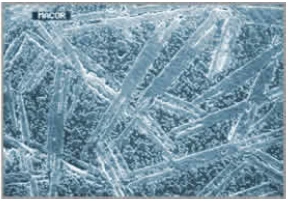

MACOR Machinable Glass Ceramic

Accuratus Corporation

Accuflect Luminaire Lighting Reflector

Accuratus Corporation

Accuflect G6 IPL Reflector

Accuratus Corporation

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle