Description

SQ Fused Silica is a premium material specifically engineered for the production of optical and photonic devices. It plays a crucial role in the fiber optic, semiconductor, and display technology sectors, in addition to various optical and laser applications. This material is renowned for being particularly free of inclusions and bubbles, which contributes to its excellent optical and physical properties. These properties include superior laser durability, refractive index homogeneity, thermal stability, and resistance to temperature shocks. Additionally, SQ Fused Silica exhibits low stress birefringence and minimal thermal expansion coefficients, making it an ideal choice for high-precision optical applications.

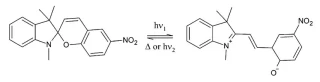

One of the standout features of SQ Fused Silica is its high OH and H2 content, which results in extremely low fluorescence. This characteristic ensures high stability under intense UV and laser radiation, making it a preferred material for high-energy applications. The material's unique composition and processing allow it to withstand demanding conditions while maintaining its integrity and performance, thus catering to the needs of advanced optical systems.

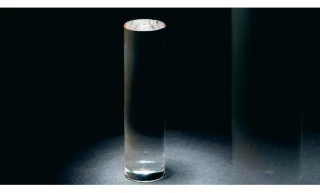

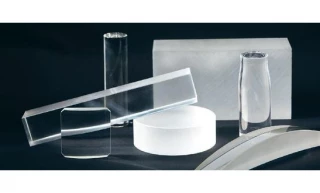

LEONI offers SQ Fused Silica in several forms, including ingots and semifinished products such as round discs, rods, plates, and blocks. Available in five distinct quality grades, these offerings are tailored to meet the specific needs of customers through meticulous measuring and selection procedures. This customization ensures that the material can be effectively used across a broad optical application range, from deep ultraviolet (DUV) to near-infrared (NIR) wavelengths. Each quality grade, from SQ0 to SQT, is designed to address specific requirements, whether for high-precision optical elements or technical applications.

In particular, the Excimergrade Fused Silica, available as SQ1 or SQ0, provides excellent transmission at 193 nm and 248 nm wavelengths. This grade is characterized by an exceptionally low level of laser-induced fluorescence (LIF), making it highly suitable for excimer laser applications. With its robust properties and versatile applications, SQ Fused Silica stands out as a critical material for innovators and manufacturers in the optics and photonics industries.

SQ Fused Silica – Ultrapure Fused Silica -SQ-E248

Specifications

| Transmission At 193 Nm: | Excellent |

|---|---|

| Transmission At 248 Nm: | Excellent |

| Path Length: | 10 mm |

| Path Length: | 40 mm |

| Laser-induced Fluorescence (LIF): | Lowest level |

| Fluorescence Signal: | Very low level |

| Substrate Material: | Fused Silica |

Features

- Exceptional Laser Durability: Designed to withstand high-energy UV and laser radiation, ensuring longevity in demanding applications.

- Refractive Index Homogeneity: Ensures consistent optical performance across the entire material, ideal for precision optical components.

- Thermal Stability and Shock Resistance: Maintains structural integrity and performance under extreme temperature variations.

- Low Stress Birefringence: Minimizes optical distortion, crucial for high-precision optical applications.

- Minimal Thermal Expansion: Features small thermal expansion coefficients, maintaining dimensional stability under varying temperatures.

- Low Fluorescence: High OH and H2 content result in extremely low fluorescence, enhancing performance in UV and laser applications.

- Versatile Applications: Suitable for excimer laser optics, DUV and UV optics components, standard optics (VIS and NIR), and technical applications such as fused silica vessels and windows.

- Customizable Quality Grades: Available in five quality grades (SQ0, SQ1, SQT) tailored to specific customer needs for homogeneity and absence of striae.

- Excimergrade Fused Silica: Available as SQ1 or SQ0, offering excellent transmission at 193 nm / 248 nm with minimal laser-induced fluorescence.

Applications

- Excimer Laser Optics: Ideal for beam guiding systems and excimer-grade components.

- DUV and UV Optics: High transmission fused silica for deep ultraviolet applications.

- VIS and NIR Standard Optics: Suitable for lenses, wafers, rods, and fibers.

- Lithography & Microlithography: Stepper lenses, photo mask blanks, and optics.

- Laser Fusion Systems: High stability under intense laser radiation.

- Technical Components: Windows, vessels, and precision optical parts.

Frequently Asked Questions

What is the difference between SQ0 and SQ1 quality grades?

What applications is SQ Fused Silica suitable for?

What are the properties of SQ Fused Silica?

What quality grades is SQ Fused Silica available in?

What is SQ Fused Silica used for?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle