Description

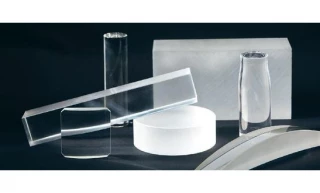

Introducing our high OH fused silica rods, meticulously crafted from undoped glass to meet the demanding requirements of the UV/VIS range. These rods are integral in the efficient manufacturing of optical components like lenses, mirrors, and plates. The purity of the material ensures exceptional optical and physical properties, characterized by an unparalleled homogeneity in the refractive index. Our SQ rods are produced using a specialized melting technology that allows for the highest concentrations of OH and H2 to be incorporated into the material.

The result is a product with optimal transmission properties in the UV/VIS range and superior laser durability. This makes our high OH fused silica rods an ideal choice for applications requiring high precision and reliability. The absence of inclusions and bubbles, combined with excellent UV transmittance and very low fluorescence, underscores the quality of these rods. Additionally, they exhibit high laser durability, low residual stress, and a very low thermal expansion coefficient, ensuring stability under varying thermal conditions.

Our rods are available in various forms, catering to different needs. The SQ version is known for its high OH content, making it suitable for applications in the UV/VIS range. For those requiring low OH content, our j-plasil rods offer high-performance fused silica for the VIS, NIR, and IR ranges. These are produced using a plasma-based deposition technique, optimizing them for IR applications. Whether for the design and production of preforms or the manufacturing of high-power optical fibers, our fused silica rods provide the foundation for superior optical solutions.

J-Plasil Fused Silica Rods

Specifications

| Material: | Fused Silica (synthetic) |

|---|---|

| Diameter: | 25 – 80 mm |

| Length: | 200 – 800 mm |

| Diameter: | 25-80mm |

| Rod Length: | 200-800mm |

| Substrate Material: | Fused Silica |

Features

- High OH Fused Silica Rods: Made from undoped glass, ideal for applications in the UV/VIS range.

- Optical Component Manufacturing: Suitable for creating lenses, mirrors, plates, and special preforms.

- Superior Material Quality: Highly pure, offering excellent optical and physical properties with high refractive index homogeneity.

- Special Melting Technology: Ensures high concentrations of OH and H2 for optimal material properties.

- Optimal Transmission: Delivers excellent transmission properties in the UV/VIS range with high laser durability.

Applications

- Preform Design & Production: Foundation for special fiber manufacturing including PCF and PM fibers.

- Optical Component Fabrication: Ideal for lenses, mirrors, and precision plates.

- Polarization Maintaining Fibers: Boron-doped rods used in Panda design fiber preforms.

- High-Power Fiber Production: Enables reliable and efficient optical fiber fabrication.

- Laser Optics: Suitable for components requiring high laser durability and low fluorescence.

Frequently Asked Questions

What is the difference between SQ and J-Plasil Fused Silica Rods?

What is the J-Plasil Fused Silica Rod used for?

What are the special dopings available for the product?

What are the applications of J-Plasil Fused Silica Rods?

What are the properties of J-Plasil Fused Silica Rods?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle