Description

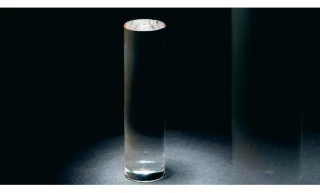

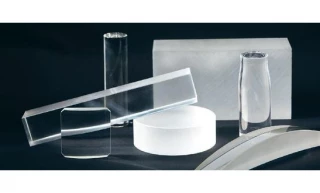

At the heart of LEONI Fiber Optics' innovation is the development and production of high-quality preforms, crafted using highly pure fused silica materials. These preforms serve as the fundamental building blocks for manufacturing high-performance special fibers and standard fibers. Our subsidiary, j-fiber, specializes in tailoring these preforms to meet specific customer requirements, ensuring they are ideally suited for applications ranging from high data rate transmission to high-power laser transmission. By adjusting the waveguide design from prototype to series production, we ensure that each preform meets the exacting standards necessary for optimal performance. **Customized

LEONI Fiber Optics excels in creating preforms with precise design and configuration. We meticulously specify the core profile, whether step-index or graded-index, and select the appropriate dopant options such as Germanium, Fluorine, Boron, or Rare-earth elements. This customization allows us to achieve the desired numerical aperture and provides the required geometry for the preform. The shape of the core and cladding is carefully determined to facilitate application-specific assembly, ensuring that every preform is perfectly suited to the needs of our clients.

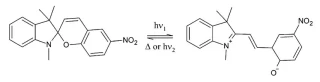

Our production process is rooted in advanced technology and stringent quality control measures. Each preform is crafted using the most suitable technology, beginning with the selection of core material from our raw material production of undoped fused silica. We employ our proprietary MCVD process for inner coating, ideal for graded-index and step-index fibers, or the PBVD process for outer coating, perfect for large core step-index fibers. Every preform undergoes strict quality monitoring to ensure it meets the goal parameters, resulting in preforms that deliver exceptional performance during the fiber drawing process for even the most demanding applications.

LEONI offers cutting-edge graded index preforms for high-performance multimode fibers, available in 50/125 and 62.5/125 designs. Our innovative MCVD production technique guarantees that each preform fulfills the specified fiber performance properties. For added convenience, graded index preforms can be delivered with a handle, facilitating secure positioning in the drawing tower. This attention to detail and commitment to quality make our multimode preforms the ideal choice for those seeking superior fiber optic solutions.

FiberTech Fluorine-Doped Step-Index Preforms

Specifications

| Material: | Doped Silica |

|---|---|

| Diameter: | 20 – 70 mm |

| Length: | 600 – 1200 mm |

| Core Composition: | SiO2 |

| Cladding Composition: | SiO2 /F |

| Preform Diameter (O.D.): | 20 - 70 mm |

Features

- High-Quality Preforms: Developed using highly pure fused silica materials, ensuring top-notch quality for high-performance special fibers and standard fibers.

- Customizable Waveguide Design: Tailored to meet specific customer demands, from prototype to series production, for high data rates or high-power laser transmission.

- Versatile Core Profile Options: Choose between step-index and graded-index core profiles, with dopant options including Germanium, Fluorine, Boron, or Rare-earth elements.

- Innovative Production Techniques: Utilizes advanced MCVD (inner coating) and PBVD (outer coating) processes for creating high-quality preforms.

- Strict Quality Monitoring: Each preform undergoes rigorous quality checks to ensure optimal performance during fiber drawing for demanding applications.

- Graded-Index Multimode Preforms: Available in 50/125 and 62.5/125 designs, suitable for high-performance multimode fibers.

- Optional Preform Handle: Graded-index preforms can be delivered with a handle for easy fixing in the drawing tower upon request.

- Bubble Size Control: Strict control of bubble sizes in the core and cladding, ensuring no bubbles in the core and limited acceptable sizes in the cladding.

- Optimal Refractive Index Profile: Nearly parabolic refractive index profile with specific index deltas for different types, ensuring precise performance.

- Numerical Aperture Precision: Offers precise numerical aperture values with tight tolerances for different preform types.

- Dimensional Accuracy: Ensures accurate outer diameter (O.D.) with minimal tolerances from rod to rod and within a single rod.

Applications

- Telecommunications: Manufacturing high-bandwidth multimode and singlemode fibers

- Laser Delivery Systems: Step-index fibers for UV-VIS-IR laser transmission

- Spectroscopy: Specialty fibers for analytical applications

- Fiber Bragg Grating (FBG) Inscription: Photosensitive germanium-doped preforms

- Medical and Industrial Lasers: High-power fiber delivery solutions

- Research and Development: Custom fiber preforms for advanced optical studies

- Microlithography: Preforms for stepper lenses, photomasks, and wafer processing

Frequently Asked Questions

What is the process technology used for producing FSI preforms?

What are the acceptable bubble sizes in FSI preforms?

What are the characteristic parameters that can be specified for FSI preforms?

What are FSI preforms used for?

What are multimode preforms?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle