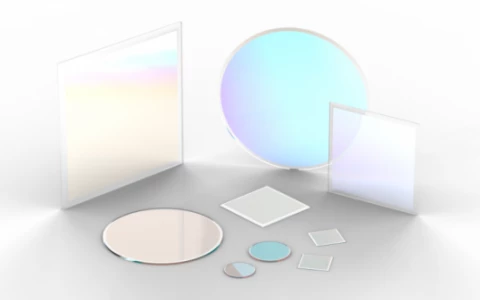

Achromatic Waveplates

Description

From crystal growth, crystal orientation and cutting, to waveplate fabrication and coating, no other waveplate supplier has as much control over the fabrication stages as G&H. Our waveplates been used in the cutting edge of research at Lawrence Livermore National Laboratory’s NIF project to the most demanding of production environments in semiconductor metrology equipment.

For all wavelength ranges, we orient, cut, and polish the optical crystals for waveplate production. Tight internal controls enable better retardation tolerances within and between production runs.

Achromatic Waveplates

Specifications |

|

|---|---|

| Type Of Waveplate: | Achromatic Air-Spaced |

| Materials: | Quartz and MgF2 |

| Mounting: | Mounted |

| Shape: | Round, Square, Rectangle |

| Operation Wavelength Range: | 633-633nm |

| Retardation: | Lambda/2 |

| Retardation Accuracy: | Lambda/500 |

| Wavefront Distortion: | <= Lambda/10 |

| Surface Quality (Scratch-Dig): | 40-20 |

Features

Crystal Quartz – standard material for UV-NIR waveplate applications

LiNbO3 – infrequently used in 1.5 ?m applications and optical frequency shifters

MgF2 – typically used in combination with Crystal Quartz for achromatic waveplates

Mica – for ophthalmology applications

Sapphire – for defense applications in extreme environmental conditions

YVO4 – waveplates for the 400 nm to 5 mm ranges

Applications

Aerospace, astronomy

biomedical

laser power control and attenuation

military

optical isolation

polarimetry

remote sensing

semiconductor metrology

spectroscopy

surveillance

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

United Kingdom

-

Sold by:

-

On FindLight:

External Vendor

Claim Gooch and Housego Page to edit and add data

Frequently Asked Questions

G&H's waveplates are used in aerospace, astronomy, biomedical, laser power control and attenuation, military, optical isolation, polarimetry, remote sensing, semiconductor metrology, spectroscopy, and surveillance applications.

G&H's achromatic waveplates are typically made of MgF2 and Crystal Quartz, and they have tight internal controls that enable better retardation tolerances within and between production runs.

G&H controls the crystal growth, crystal orientation and cutting, waveplate fabrication, coating, assembly, and metrology stages of the manufacturing process for their waveplates.

G&H uses Crystal Quartz, LiNbO3, MgF2, Mica, Sapphire, and YVO4 for their waveplates.

G&H offers custom specifications for specialty waveplate designs such as off-axis or true-zero order waveplates.