Description

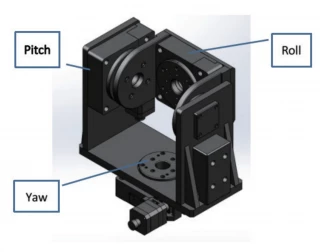

The X-JOY3 joystick is a cutting-edge device designed to revolutionize manual control in motion applications. With its ability to manage up to three axes, each with customizable sensitivity and velocity profiles, the X-JOY3 stands out as a versatile tool for precise control. Its compact bench-top design allows for seamless integration into any workspace, offering the flexibility of manual operation with or without a computer connection.

One of the standout features of the X-JOY3 is its intuitive operation. The joystick comes equipped with eight programmable keys, enhancing user convenience by enabling functions such as storing and recalling positions. These keys can be customized to perform specific commands, making automation tasks simpler and more efficient. The joystick's intuitive ASCII protocol further simplifies complex automation sequences, ensuring that users can achieve their desired outcomes with minimal effort.

Compatibility is at the heart of the X-JOY3's design. It works seamlessly with all Zaber motor controllers and devices featuring built-in controllers, making it an ideal choice for users already invested in the Zaber ecosystem. When used in conjunction with other X-Series products, the X-JOY3 can share power across devices in the chain, minimizing the need for multiple power supplies and streamlining the setup process.

Programmable 3-Axis Joystick X-JOY3

Specifications

| Accessory Type: | Joysticks |

|---|---|

| Communication Interface: | RS-232 |

| Communication Protocol: | Zaber ASCII (Default), Zaber Binary |

| Maximum Current Draw: | 50 mA |

| Power Supply: | 24-48 VDC |

| Power Plug: | 2-pin Screw Terminal |

| Data Cable Connection: | Locking 4-pin M8 |

| Manual Control: | 3-axis joystick, 8 programmable keys |

| LED Indicators: | Yes (power, communication, error) |

| Operating Temperature Range: | 0-50 °C |

| RoHS Compliant: | Yes |

| CE Compliant: | Yes |

| Weight: | 0.52 kg |

Features

- Controls Up to Three Axes: Each axis comes with programmable sensitivity and velocity profile, allowing for precise motion control.

- Compact Bench-Top Design: Ideal for manual control with or without a computer, making it suitable for various setups.

- Eight Programmable Keys: Customize functions like storing and recalling positions for enhanced efficiency and ease of use.

- Intuitive ASCII Protocol: Simplifies complex automation tasks, making it easier to integrate with existing systems.

- Compatibility: Works seamlessly with all Zaber motor controllers and devices with built-in controllers.

- Power Sharing: When connected with other X-Series products, power can be shared between devices, reducing the need for multiple power supplies.

- Communication Interface: RS-232 with Zaber ASCII (Default) and Zaber Binary protocols for flexible connectivity.

- Manual Control: Features a 3-axis joystick and 8 programmable keys for versatile control options.

- LED Indicators: Includes indicators for power, communication, and error status for easy monitoring.

- Operating Temperature Range: Designed to operate efficiently in temperatures ranging from 0-50 °C.

- Compliance: RoHS and CE compliant, ensuring adherence to international safety and environmental standards.

- Lightweight Design: Weighs only 0.52 kg (1.146 lb), making it easy to handle and integrate into various setups.

Applications

- Manual XY or XYZ Positioning: Ideal for laboratory setups requiring intuitive manual motion control.

- Microscopy and Imaging: Enables precise positioning in optical and imaging applications.

- Automation System Integration: Simplifies integration into existing automated workflows for enhanced flexibility.

- Prototyping and R&D: Useful for development environments requiring rapid manual adjustments and programming versatility.

Frequently Asked Questions

What is the X-JOY3 joystick used for?

How many axes can the X-JOY3 control?

Can the X-JOY3 be used with or without a computer attached?

What is the compatibility of the X-JOY3 with other devices?

How many programmable keys does the X-JOY3 have?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle