Description

Introducing the IS50A-1KW-RMT-D0, Gentec-EO's flagship high-power joulemeter, engineered to deliver unparalleled precision in laser energy measurement for industrial and research applications. With its robust design, NIST-traceable calibration, and innovative features, this high-power joulemeter sets a new standard in laser measurement technology. Suitable for a wide range of high-power lasers, the IS50A-1KW-RMT-D0 offers reliability and accuracy for professionals in optics laboratories, material research, manufacturing, and beyond.

IS50A-1KW-RMT High-Power Joulemeter: 1kW Laser Energy Measurement with NIST-Traceable Calibration & Resistant Coating

Specifications

| Max Measurable Energy: | 1000 mJ |

|---|---|

| Max Repetition Rate: | 1000 Hz |

| Effective Aperture: | 50 mm |

| Spectral Range: | 0.19 – 2.5 um |

| Noise Equivalent Energy: | 1 mJ (Typical value) |

| Maximum Pulse Width: | 10 μs |

| Energy Calibration Uncertainty: | ±4 % (At 532 nm and 1064 nm) |

| Maximum Incidence Angle: | ±25° for beam diameter < 12mm, ±5° for beam diameter > 12mm |

| Maximum Divergence: | 10° (half-angle) |

| Back Reflections: | 12%, concentrated in a cone with 15 degrees half-angle |

| Calibrated Spectral Range: | 532 nm, 1064 nm, and 1070 nm |

| Maximum Average Power Density: | 5 kW/cm² (At 1064 nm, CW) |

| Maximum Energy Density: | 400 mJ/cm² (At 532 nm and 1064 nm, 7 ns) |

| Maximum Power: | 1 kW |

| Cooling: | Water |

| Aperture Diameter: | 50 mm |

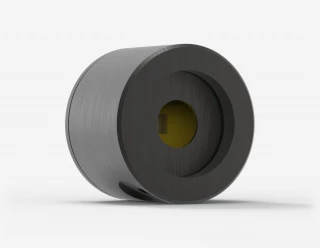

| Absorber: | Pyroelectric |

| Weight: | 4 kg |

Features

- High-Power Measurement: This high-power joulemeteris capable of measuring laser energy up to 1 kW average power, ideal for high-demand applications.

- NIST-Traceable Calibration: Ensures accurate and reliable measurements, traceable to international standards.

- Advanced Coating Technology: Features a proprietary resistant coating with high damage thresholds, significantly outperforming standard "white" coatings.

- Flexible Output Options: Includes Smart DB15 connector with calibration data, INTEGRA with USB output, RS-232 output, and USB output with external trigger.

- Optimized Physical Design: Water-cooled system with a 50 mm aperture diameter, housed in a compact and durable frame.

- Rapid Response Time: Achieves a typical rise time of 30 µs, suitable for fast-paced environments.

- Spectral Range Adaptability: Calibrated for 532 nm, 1064 nm, and 1070 nm, covering a broad range of laser types.

Applications

- Optics Laboratories: This joulemeter is ideal for research and development settings requiring precise laser measurement.

- Material Research: Crucial for experiments involving laser-material interactions and processing.

- Optics Manufacturing: Ensures quality control and calibration in the production of optical components.

- Medical Industry: Supports the development and maintenance of laser-based medical devices.

- Semiconductor Manufacturing: Essential for processes involving laser etching and cutting in semiconductor fabrication.

- Aerospace Industry: Used in the testing and development of aerospace components and systems where high-power lasers are employed.

Frequently Asked Questions

What is the maximum laser power the IS50A-1KW-RMT-D0 joulemeter can measure?

The IS50A-1KW-RMT-D0 joulemeter is designed to accurately measure laser energies up to 1 kW average power, catering to high-power laser applications across various industries.

Is the calibration of the IS50A-1KW-RMT-D0 joulemeter traceable to any standards?

Yes, the IS50A-1KW-RMT-D0 joulemeter features NIST-traceable calibration, ensuring that its measurements are reliable, accurate, and compliant with international measurement standards.

Can the IS50A-1KW-RMT-D0 handle different laser beam sizes?

Absolutely. With its 50 mm aperture diameter, the IS50A-1KW-RMT-D0 is adept at measuring a wide range of beam sizes, making it versatile for various laser types and applications.

What makes the coating on the IS50A-1KW-RMT-D0 unique?

The IS50A-1KW-RMT-D0 is equipped with a proprietary resistant coating that boasts damage thresholds significantly higher than standard coatings, enhancing durability and performance in demanding environments.

What output options are available with the IS50A-1KW-RMT-D0?

This joulemeter offers flexible output options, including a Smart DB15 connector with all calibration data, INTEGRA with USB output, RS-232 output, and USB output with an external trigger, to fit various measurement setups.

How does the IS50A-1KW-RMT-D0 improve safety in measurement environments?

Its design minimizes back reflections, which are confined within a narrow angular cone, reducing the risk associated with stray reflections in high-power laser applications.

Who can benefit from using the IS50A-1KW-RMT-D0 joulemeter?

Professionals in optics laboratories, material research, optics manufacturing, the medical and semiconductor industries, and aerospace sector will find the IS50A-1KW-RMT-D0 invaluable for its precision, reliability, and adaptability in high-power laser measurements.

Similar Products

Gentec-EO QE195LP-S-MB: 195mm High-Precision Laser Energy Detector

Gentec-EO

PE3B-IN-D0 Photodiode Detector

Gentec-EO

PE3B-SI-D0 Photodiode Detector

Gentec-EO

PE5B-GE-D0 - Photodiode Detector for Laser Energy Measurement

Gentec-EO

Gentec-EO Pyroelectric Detector QE65ELP-H-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65ELP-S-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-H-MB-QED-D0

Gentec-EO

Gentec-EO QE65LP-H-MB-D0 Pyroelectric Detector

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-S-MB-QED-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-S-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE25HR-H-MB-QED-D0

Gentec-EO

QE25LP-S-MB-QED-D0 Pyroelectric Detector for Laser Energy Measurement

Gentec-EO

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle